2021-12-17

With the continuous development of society, the evolution of our intelligent equipment is changing with each passing day, and people have increasingly pursued personalization. Increasingly complex shapes mean that higher demands are placed on dispensing equipment, which needs to deal with higher dispensing accuracy! More flexible dispensing Angle!

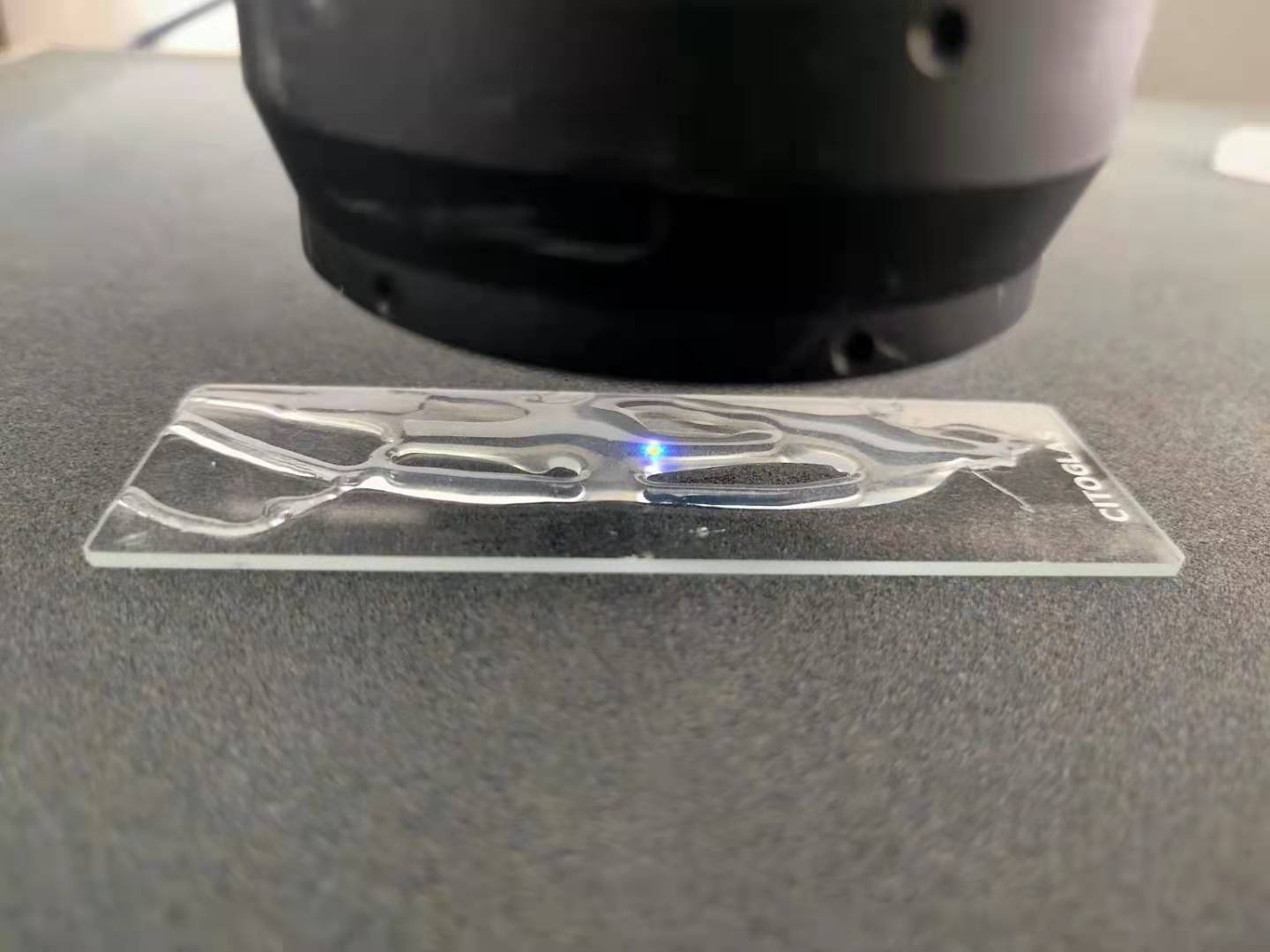

At present, when the mobile phone center plate and screen module are fitted, it is necessary to point a circle of transparent UV glue on the center plate. This glue can only be measured perfectly using the spectral confocal sensor due to the white reflection. Due to the composite light characteristics of the spectral confocal sensor, the height and width of the glue can be measured perfectly at high speed.

Due to the characteristics of the glue itself: liquid, molding characteristics: with arc, material characteristics: transparent or translucent.

The glue pellets generated in the dispensing process can currently only pass the inspection of the visual system. In the production must ensure that the dispensing route is consistent and stable, and through the dispersion confocal measurement sensor system can control many parameters in many quality inspection standards. The glue ball must be positioned in the center with respect to the other structures. Abnormal material accumulation at the beginning and end of dispensing can be detected. Dispersion confocal measurements can detect even the notch.

Due to the improvement of dispensing process demand, the vertical spectral confocal displacement sensor is promoted, and the vertical spectral confocal displacement sensor is widely used in semiconductors, aerospace, medical food packaging, 3C and so on.

In the field of 3C, the requirements for precision dispensing are getting higher and higher, which requires real-time detection of the glue height to achieve closed-loop control of precision dispensing. Because the glue has a variety of transparent and non-transparent materials, and the glue profile is more complex, and the tilt Angle is large, the traditional laser sensor can not accurately measure the height of the glue profile. The D82 probe has a measurement Angle that can be applied to a variety of glue profile height measurements, especially in the round hole glue high detection has a unique advantage.

Therefore, the current common practice in the industry is to use a large Angle spectral confocal sensor, because the spectral confocal sensor uses white light, white light is composite light, there will always be light can be reflected back, and for the arc, increase the reflection Angle of the light pen (45°), so as to perfectly measure the outline of the white transparent glue.