2020-05-14

The working principle of the laser displacement sensor is introduced to you, and we know that many tools and products of modern technology have replaced the previous complex manual operation. For example, the displacement sensor is a high-tech product, but many customers ask Xiao Bian how it works? Erector displacement sensor manufacturers will now share with you!

First, the principle of laser displacement sensor

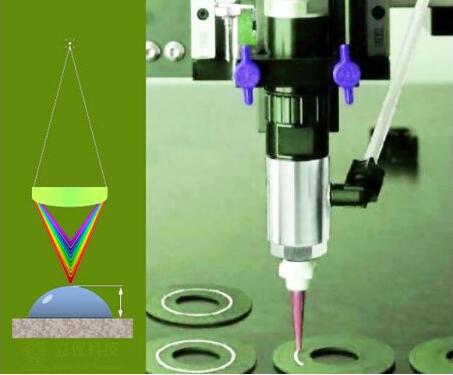

During the operation of the laser displacement sensor, the laser displacement transmitter will emit a red laser from the lens to the surface of the object, and a series of reflections will occur on the surface of the object, in which a beam of light will return to the laser displacement sensor as reflected light. At this time, the detection will be based on the Angle of light reflection and the distance of the laser displacement sensor.

The position of the beam at the receiving element is processed through analog and electronic digital processing, and after the internal microprocessing analysis, the corresponding output value is calculated, and then the output value is adjusted, and then the beam is emitted to the object, and then the beam can be adjusted the displacement distance.

Second, the use of laser displacement sensors

1. Length measurement

The part under test is placed at a specified position on the conveyor belt, the laser sensor detects the part, and the part is measured with a trigger laser scanner to obtain the length of the part.

2. Check consistency

A number of laser sensors are arranged in a line along the inclined direction of the motion of the workpiece to be measured, and the measured value is directly output through one sensor. In addition, software can be used to calculate the measured values and read out the results based on the signal or data.

3. Inspection of electronic components

Using two laser scanners, the component under test is placed between the two and the data is read out by the sensor to detect the accuracy and completeness of the component dimensions.

Third, laser echo analysis of the principle of laser displacement sensor

The laser displacement sensor uses the principle of echo analysis to measure the distance and achieves a certain precision. The sensor consists of a processor unit, an echo processing unit, a laser transmitter, a laser receiver and other components. The laser displacement sensor fires a million laser pulses per second at the detection object and returns to the receiver through the laser transmitter, and the processor calculates the time required for the laser pulses to meet the detection object and return to the receiver, thus calculating the distance value, and the output value is the average output of thousands of measurements. The so-called pulse time method. Laser echo analysis is suitable for remote detection, but the measurement accuracy is lower than laser triangulation, and the maximum detection distance can reach 250 meters.

This is the introduction of the working principle of the laser displacement sensor. Shenzhen Liyi Technology Co., Ltd. is a professional production and sales of displacement sensor, laser displacement sensor, Angle displacement sensor, spectral confocal sensor company, in need of friends can call to consult Liyi fiber coaxial displacement sensor manufacturers. Welcome your call!