2023-06-09

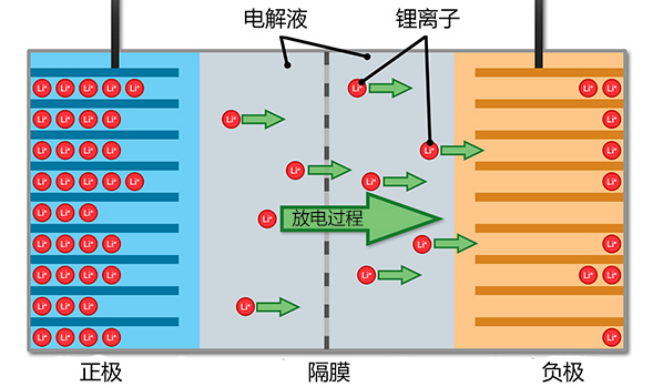

From mobile phones and sports bands to various electric vehicles, lithium-ion batteries are a key energy supply device. Lithium-ion batteries are light weight, high energy density, long cycle life, and do not pollute the environment. Due to the wide application of lithium-ion batteries, they are also known as the "energy metal of the 21st century".

About lithium-ion batteries

Because lithium-ion batteries are usually composed of four parts: positive electrode material, negative electrode material, isolation film and electrolyte. The manufacturing process of the electrode plate consists of three parts: first, the specific proportion of active substances, conductive agents, binders and solvents are fully mixed to make the electrode load; Second, the electrode load is evenly coated on the collector, the positive collector is generally aluminum foil, the negative collector is generally copper foil; Finally, the electrode plates of different sizes were obtained by drying, rolling and cutting. With the development of science and technology, so as to leave more space for positive and negative electrode materials, the thinner the diaphragm is more stringent on the process requirements, and the roughness of positive and negative electrode materials is lower in the case of ensuring the safety of lithium batteries and charging and discharging efficiency, which has extremely high requirements for the electrode surface roughness.

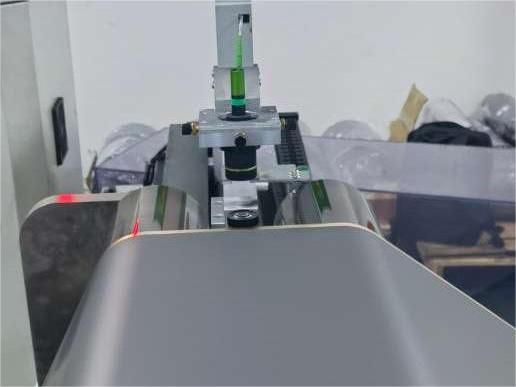

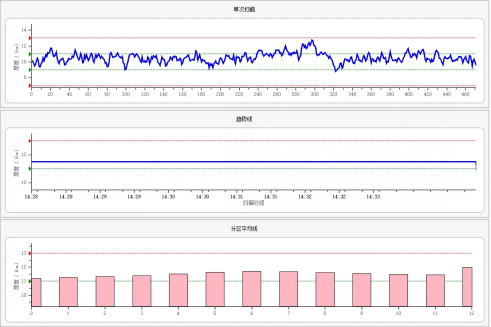

Spectrometer technology spectral confocal measurement scheme

The surface roughness index Ra of the lithium-ion battery electrode is usually several microns, and the non-contact scanning of the electrode surface using the spectroscopic confocal displacement sensor can obtain the measurement data of the electrode surface within a few minutes. The roughness analysis function of the analysis software can be used to derive the measurement report including Ra/Rz and other roughness indices.