2020-05-11

Today, we will introduce you to the application of color laser coaxial displacement meter in the dispensing industry. In order to obtain a more extreme visual experience, after Liu Haibing, integrated screen, sliding screen and double-sided screen, and digging screen also came into being. The hollowing of the burrow screen is divided into two processes: through hole and blind hole.

A through-hole is a hole punched in the screen, which is more conducive to the imaging of the front camera. After all, there are fewer obstacles, but the process is relatively complex, the quality control requirements are more stringent, and the yield is lower. Another problem is that the aperture is large, generally more than 6.5 mm. Blind hole is to put the camera under the screen, the process is relatively mature, high output, low cost, and small aperture. However, due to the addition of a layer of liquid crystal, the transmission will inevitably be affected, and the image quality of the camera will also be affected to a certain extent.

The "through hole" can effectively reduce the screen layer's occlusion of the front camera, so that it is more advantageous when taking photos to obtain light. Therefore, only where the screen is perforated and the camera need to be connected to solve the problem. This process requires a lot of glue. If the glue height is not consistent, the resulting screen image will have gaps and unnatural connections. Spectral confocal sensor can solve this problem well. It can not only fully measure the height of the glue, but also the width and high-speed sampling frequency. It is more suitable for online automatic devices.

However, there is also the problem that the visual integrity of the "through hole" is much worse. Because there is no need to consider the impact of the screen on the camera, the "through hole" on the screen will be larger than the camera itself, that is, larger than the "blind hole" hidden under the screen.

When installing a camera module with a hole-out screen, there are two difficulties in detecting the glue because the glue dispensed is transparent. One is that the shape of the glue after dispensing is curved, which is a good test of the mirror reflection Angle of the light pen. If it is detected with a monochromatic laser sensor, the light will penetrate, the laser will penetrate directly into the rubber bottom, or the reflection Angle caused by the arc can not reflect the light back.

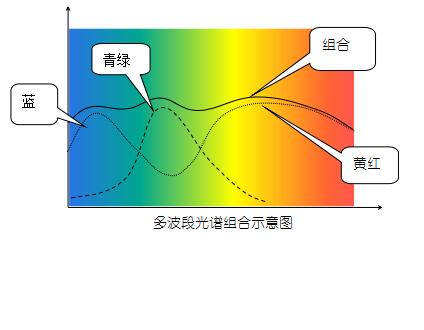

Therefore, the current common practice in the industry is to use color laser coaxial displacement meters. Because color laser coaxial displacement meters are based on the principle of spectral confocal sensors, white light is used, and white light is synthetic light, and there is always light that can be reflected back. In addition, for curved surfaces, the Angle of reflection (45) of the light pen is increased, making it possible to measure the outline of the white transparent adhesive perfectly. Shenzhen Liyi Technology Co., Ltd. is a professional production and sales of displacement sensor, laser displacement sensor, Angle displacement sensor, spectral confocal sensor company, in need of friends can call to consult Liyi fiber coaxial displacement sensor manufacturers. Welcome your call!