2020-03-19

Comparison of the principle of spectral confocal displacement sensor and laser displacement sensor

Have you ever wondered how to protect your investment when materials, colors and processes are updated too quickly? The product structure is becoming more and more fine, and the requirements are becoming higher and higher, how to improve the measurement accuracy? Product structure is becoming more and more complex, how to avoid measurement blind spots? Today, the spectrometer spectral confocal sensor manufacturers will answer for friends who have doubts:

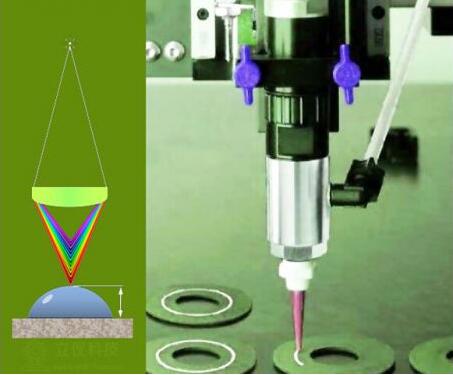

First, spectral confocal principle

1. A beam of white light (or multi-wavelength mixed light) passes through a small hole, focuses different wavelengths on the optical axis through the lens, dispersively forms a rainbow distribution band, shines on the sample, and part of the reflected light on the surface is reflected back.

2. The light that is not irradiated at the intersection of the optical axis and the surface of the object passes through the spectroscopic part, and the light irradiated around the other small hole is blocked and cannot be irradiated to the spectral analyzer, and will not interfere with the measurement.

3. The light shining at the intersection of the optical axis and the surface of the object passes through the splitter component and illuminates the spectral analyzer through the small hole. According to the wavelength calculation, the distance between the lens and the measured object can be obtained.

Second, the advantages of spectral confocal principle

1. Resolution: Theoretically the wavelength can be subdivided all the way down, and the ideal lens has a fairly high resolution.

2. Good temperature stability: the lens itself does not heat, and the temperature drift is small. For micron and submicron measurements, temperature drift is key.

3. Automatic focusing: Within the range, the position of the measured object changes up and down, and the corresponding wavelength of light is focused to the surface of the object.

4. High horizontal resolution: from top to bottom, it is always in the focus, and the measured light spots are small, which can distinguish the small contour changes on the measured object.

5. Modular miniaturization: the lens and controller can be connected through optical fiber, the transmission distance is far, the lens can be made small, easy to install side by side.

6. FM anti-interference: the wavelength is an FM signal, which is not sensitive to AM interference such as light intensity change. Optical fiber is not sensitive to electromagnetic interference and lightning surge.

7. Transparent material thickness measurement: When the measured object is transparent and has two surfaces, there will be two wavelengths of light returned to obtain the thickness value.

8. Holography: In theory, the wavelength of any beam of light returning to the spectral analyzer carries distance information, and some light is shielded.

9. High safety: long life LED light source, small power white light, safer than laser for the human eye, not limited to the laser hazard level.

10. High protection: The controller has high protection level, and the optical fiber can be provided with stainless steel jacket version to prevent pests and rats from biting.

These are the principles of the spectral confocal displacement sensor compared with the laser displacement sensor, as well as the advantages of the spectral confocal principle. As long as you look for Shenzhen spectrometer spectral confocal sensor manufacturers, you can solve these problems and doubts raised at the beginning. Welcome to inquire!