2020-03-10

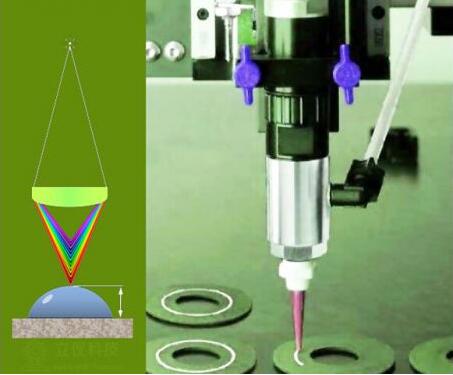

Spectral confocal measurement technology analyzes the focal position of different wavelengths of light on a specific surface to perform high-precision dimensional measurement and microscopic morphology analysis. According to this measurement principle, a specific wavelength of light may be focused on the surface of the sample, while for a transparent sample, two different wavelengths of light will be focused on the inside of the sample. These are the two measurement modes provided by spectral confocal, the former is the displacement measurement mode, the latter is the thickness measurement mode. The following is a brief introduction of Shenzhen Liyi Technology:

1. Displacement measurement mode

The displacement measurement mode outputs the height value in the z direction, reads the displacement of XY, and directly outputs the point cloud coordinates. This model is consistent with three coordinate, structured light, laser triangulation and other measurement methods, but the difference is that spectral confocal supports reflector measurement and has sub-micron measurement accuracy.

The displacement measurement mode is suitable for most accurate dimensional measurement scenarios, and you can select point, line, and surface measurement samples. Point measurement is suitable for measuring the vibration of objects and the height of liquids, and outputs values in the z direction at different times to aid analysis. Linear measurement can continuously record the Z-direction value of the moving sample surface for break detection and 2D dimensional analysis. Surface measurement provides complete three-dimensional morphological data of the sample surface, which can be analyzed for comprehensive roughness and other items.

2. Thickness measurement mode

When measuring transparent samples (such as glass and lenses), two different wavelengths of light will be focused on the front and back of the sample, introducing the refractive index parameter of the sample, and then the thickness value of the sample can be calculated. Compared with traditional contact measurement tools such as vernier calipers, spectral confocal measurement has all the advantages of non-contact optical measurement, but also has the property that the sample thickness value can be obtained by unilateral measurement.

Since the refractive index directly affects the accuracy of the thickness measurement data, the refractive index of the sample should be confirmed at the beginning of the measurement. The index of refraction can refer to the value of the same material, but in order to obtain a more accurate thickness measurement, it is necessary to measure the refractive index of the sample with a refractometer.

Now we know what are the two measurement modes of spectral confocal? The two measurement modes of spectral confocal focus can be switched freely through the software interface without the need to restart the device or system. Therefore, whether the surface size of the sample is measured, the thickness of the transparent material is measured, or the appearance size and thickness of the transparent sample are obtained at the same time, the spectral confocal measurement technology can be left to correspond.