2023-02-22

Laser displacement sensor is an automatic optical sensing technology for measuring distance and contour surfaces. It works by firing a laser beam, reflecting off the target surface or area, and then converting the time it takes for the beam to return into a distance measurement. Its main application is dimensional measurement, allowing accurate measurement of length, distance and roughness profiles. Laser displacement sensors are also used in industrial automation, robotics and machine vision applications. The following editor will introduce the laser displacement sensor to you in detail:

First, what is the laser displacement sensor.

Laser displacement sensor is an automatic optical sensing technology for measuring distance and contour surfaces. The system works by firing laser light from a laser source. The laser beam is then reflected off the target surface or area. The time it takes for the beam to cover the distance and return is then converted into a distance measurement or profile.

The laser displacement sensor generally consists of a laser source, an optical detector and a processor.

The laser source is usually a laser diode with a wavelength appropriate to the target region and its optical properties. The laser beam produced by the laser diode is directed to the target surface or area. The beam is then reflected back to the detector. Depending on the application, the beam can be modulated with a certain range of pulse frequencies. The beam is detected by an optical detector. The detector converts the light into an electrical signal, which is then sent to the processor. The processor then processes this information and sends the measurement data to a digital display or computer. This data can be used for further analysis or to control automated processes.

Application program:

1. Laser displacement sensors are widely used in industrial, scientific and research fields. Its main use is measurement to obtain accurate measurements of length, distance and surface roughness.

2. Laser displacement sensors can also be used to measure the gap between two planes, for example in the automotive industry. It is also used in 3D printing to measure the accuracy of parts. In addition, it is used in dimensional measurement and assembly systems in the aerospace and defense industry.

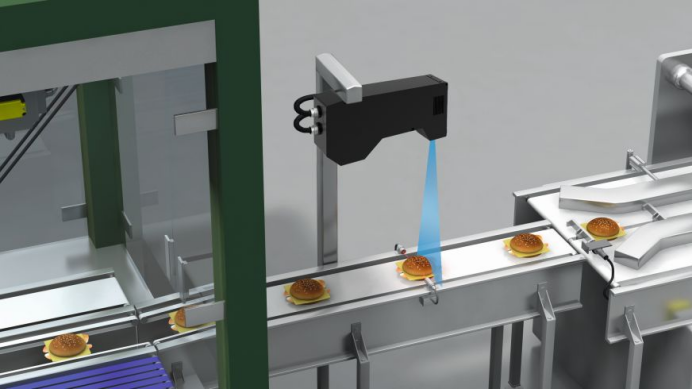

3. Laser displacement sensors are also used in industrial automation, robotics and machine vision. In these areas, its precise measurements enable efficient production and quality control. It is also widely used in microelectronics and medical device manufacturing to measure tiny distances between components.

Advantages:

Compared to other sensing technologies, laser displacement sensors have many advantages. These include:

* High precision - Laser diodes produce laser beams of precise size and shape, giving them extremely high accuracy.

* Easy to integrate laser displacement sensors Small size, light weight, easy to install on the device.

* Non-contact sensing - The laser beam provides non-contact distance sensing, which is useful in applications where physical contact is not required or possible.

* Fast and reliable - Laser detection is fast and provides repeatable measurements.

Automation potential - Laser displacement sensors can be used in automated systems where the measured data is used to control process parameters.

Laser displacement sensor is an automatic optical sensing technology for measuring distance, size and surface profile. It is a highly accurate and reliable form of non-contact sensing and therefore suitable for many industrial and scientific applications. Its wide range of advantages make it ideal for many measurement and automation applications.