2022-12-03

The generation and development of any industry is inseparable from the progress of science and technology, which is also the promotion of the industry caused by the continuous expansion of market demand, prompting the relevant personnel to constantly update the product, and the development of spectral confocal displacement sensor is also changing with each passing day.

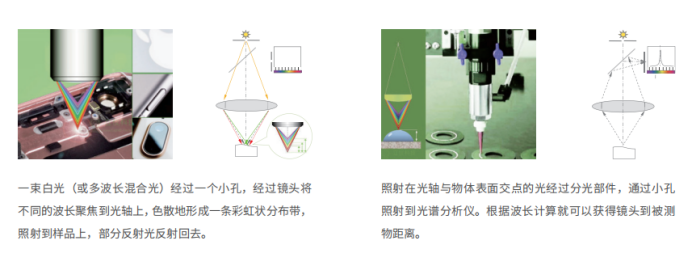

Principle of spectral confocal displacement sensor:

A beam of white light (or multi-wavelength mixed light) through a small hole, through the lens to focus different wavelengths on the optical axis, dispersively form a rainbow distribution band, shine on the sample, part of the reflected light reflected back; The light shining at the intersection of the optical axis and the surface of the object passes through the spectral component, shines through the aperture to the spectral analyzer, and the distance from the lens to the measured object can be obtained according to the wavelength calculation. Light that does not shine at the intersection of the optical axis and the surface of the object passes through the splitter and is blocked around the other small hole.

Spectral confocal displacement sensor system composition:

In the system of spectral confocal sensor, the measuring range of the system is affected by four factors: the spectrum distribution range of the light source; The axial color difference of the dispersive lens in the working band; The working band of the spectrometer; The operating frequency band of the optical fiber coupler. The selected white LED light source has a spectral distribution wavelength range of 400-800nm. Therefore, in the design process of the spectral confocal sensor, the operating band of the dispersive lens, spectrometer and fiber coupler should be as consistent as possible with the band of the light source. The measuring range of the system is its usual dispersion objective. The axial color difference in the operating band of a spectral confocal sensor.

In addition to the axial chromatic difference, the following factors should be considered in the design of the dispersive lens: Firstly, the resolution of the spectral confocal sensor should be improved by increasing the object-side numerical aperture; Secondly, increasing the numerical aperture of the image side can improve the utilization rate of the light source. Then reducing the spherical error of the system can improve the accuracy. The system structure of the spectral confocal sensor should be relatively easy to assemble and adjust.

If the spherical aberration system is to be corrected, the structure becomes complicated, so the dispersive lens of the spectral confocal sensor is designed to achieve better results with very few lenses. The optical system of the spectral confocal sensor can be seen as two parts, one part is the achromatic field mirror, the focus is at the light source, the point light source collimation into parallel light, the other part is the dispersive objective lens, its role is to focus the wavelength of parallel light at different positions on the axis, generating spectral dispersion, which is what achromatic lenses and aspherical lenses can do. A fiber coupler with high coupling efficiency and a spectrometer with a resolution of 0.5nm in the range of the light source are selected.

Applications of spectral confocal displacement sensors:

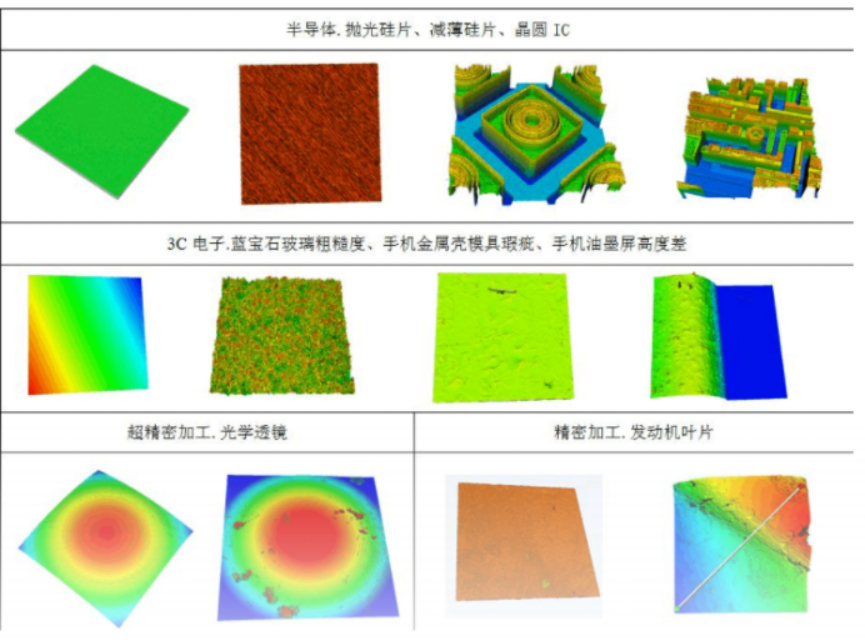

1, surface roughness measurement application Surface roughness refers to the micro-level condition with small spacing and small peaks and valleys formed on the workpiece processing surface due to different processing methods, the accuracy of machine tools and tools, vibration and wear and other factors, which is an important measure of surface quality. Related parts wear, sealing, lubrication, fatigue, grinding and other mechanical properties. Surface roughness measurement can be divided into contact measurement and non-contact measurement. The stylus contact measurement is easy to scratch the measuring surface, the tip is easy to wear, the measurement efficiency is low, and the complex surface can not be measured, while the non-contact measurement can achieve non-contact, efficient, online real-time measurement, and become the development direction of the future roughness measurement. At present, the commonly used non-contact methods mainly include interference method, scattering method, speckle method, focusing method and so on. Focusing method is relatively simple and practical. A simple measuring device is built by using the confocal displacement sensor to measure the roughness of the valve cover of the film gas meter without contact, so as to judge whether the seal of the valve cover is qualified. Based on the spectral confocal sensor, the surface roughness of the roughness sample was measured without contact by the two-dimensional nano-measuring and positioning device built by the spectral confocal sensor, and the uncertainty evaluation of the measurement results was carried out, and the U95 was 13.9%.

2, contour, geometric size measurement application With the development of machining level, more and more small complex workpieces need profile measurement and precision size measurement, such as the measurement of small round chamfer, small workpiece inner wall groove size measurement. Some precision optical components also need non-contact profile measurement to avoid scratching the optical surface during contact measurement. These measurement problems that are difficult to solve with traditional sensors can be solved by building a measurement system with spectral confocal sensors. Aiming at the problem of turbine disk profile detection, the spectral confocal displacement sensor is used to design the online detection system of turbine disk profile. The two-dimensional dimension measurement of ultra-precision parts is realized by using the spectral confocal sensor as the probe head through the self-built two-dimensional nano measuring and positioning device. Using laser confocal displacement meter and two dimensional precision control micro-motion table, the surface fluctuation depth of helioscope in Western Han Dynasty was scanned to explore the reflection imaging principle of light mirror.

3, film material thickness measurement application Because the spectral confocal sensor for different reflectors reflect back monochromatic light wavelength is different, so for the thickness of the material precision measurement has a unique advantage. Optical glass, biofilm, parallel plate, etc., the two reflectors will reflect different wavelengths of monochromatic light, and then only one sensor, you can calculate the thickness, the measurement accuracy of up to micron, and no damage to the measured surface. The application of spectral confocal displacement sensor to measure the thickness of transparent materials is discussed. The measuring error range of this system is about 0.005mm. The method of measuring the thickness of parallel plate and the center thickness of optical lens by using spectral confocal sensor is provided, and the influence of material dispersion on the thickness measurement accuracy is analyzed theoretically. In order to explore the relationship between the thickness of the film prepared by the fluid drop mode and the drop mode, Reynolds number and the tilt Angle of the bottom plate, a spectral confocal sensor is used to monitor the thickness of the film prepared in real time. The thickness and distribution of metal films with a thickness of 10 ~ 100μm are measured accurately by using a white light confocal sensor set mounted on the top. The measurement uncertainty is analyzed, and the measurement uncertainty of the system is about 0.12μm. Spectral confocal technology is a high-precision, non-contact optical measurement technology, which establishes a set of coding rules for axial distance and wavelength. As a sub-micron sensor for fast and accurate measurement, the sensor based on spectral confocal technology has been widely used in industrial measurement fields such as surface micro-shape measurement, thickness measurement, displacement measurement, on-line monitoring and process control. Looking forward to its future, with the development of spectral confocal sensing technology, it will be applied more and more in microelectronics, linewidth measurement, nano measurement, ultra-precision geometric measurement and other fields.