2022-09-02

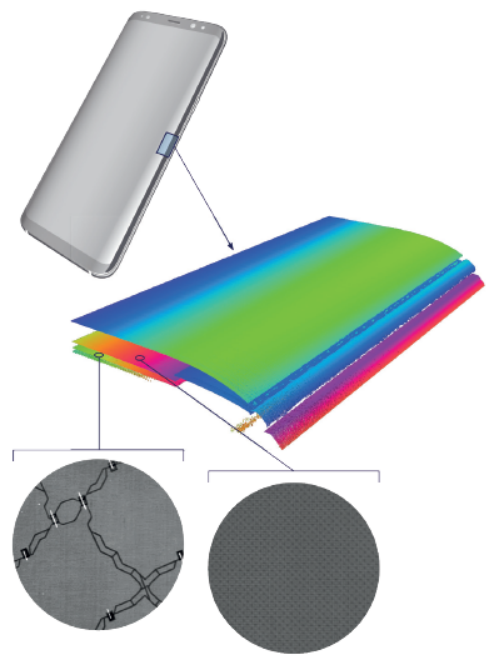

With the rapid update of the appearance design of 3C products and the continuous upgrading of material technology, spectral confocal sensors have been used more and more in the automatic measurement of 3C products in the manufacturing process in recent years, and spectral confocal displacement sensors have played their unique advantages. Spectral confocal sensors have been widely used in mobile phone surface profile, mobile phone chip, middle frame segment difference, LOGO. Precision measurement scenarios such as segment differences, camera modules, and coating defects.

Spectral confocal displacement sensor glass profile scanning

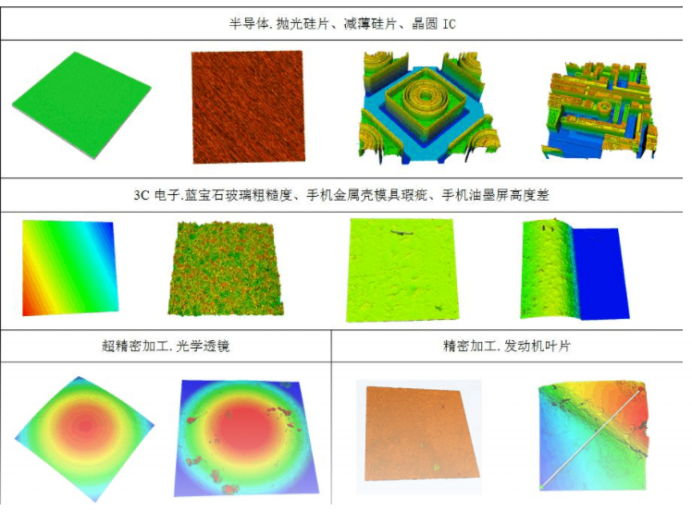

In the semiconductor design, manufacturing, packaging in all aspects of the repeated detection, testing to ensure product quality, so as to develop a device that meets the requirements of the system. The cost of defects related failures is high, ranging from tens of dollars at the IC level, to hundreds of dollars at the module level, to thousands of dollars at the application level. Therefore, testing equipment from design verification to the entire semiconductor manufacturing process has an irreplaceable important position. Spectroconfocal sensors with high resolution, high accuracy and reliability play a very important role in precision measurement applications such as wafer surface profile, chip seal detection and tin ball lead welding.

Mold is the basic process equipment of industrial production, known as the "mother of industry". Molds are widely used in a wide range of fields, 75% of roughing industrial parts, 50% of finishing parts are formed by molds, and most plastic products are also formed by molds. With the structural design of industrial products becoming more and more complex, the mold contour is becoming more and more diverse, the geometric shape is becoming more and more complex, and the proportion of free surface is increasing. Therefore, the manufacturing, processing and dimensional detection of precision and complex molds are also put forward higher requirements.

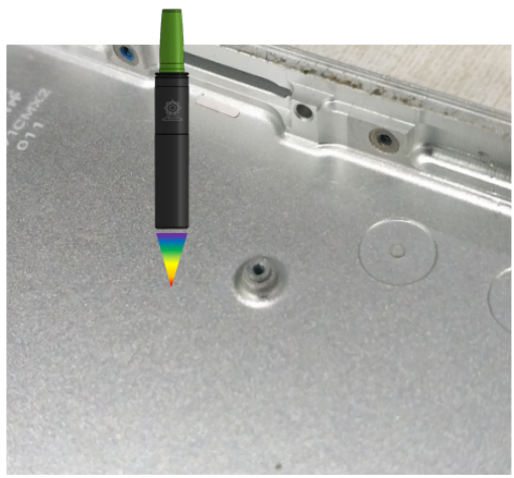

Aperture depth measurement of spectroscopic confocal displacement sensor

Spectroscopic confocal sensors can detect any material and surface: including mirror, glass, ceramic, semiconductor, high-light metal and other surfaces can be measured at the nanoscale; The ultra-high sampling frequency can be used in the production line to replace manual and improve the pass rate, and the measurement range is very wide, almost no dead Angle, can solve the laser triangulation measurement can not avoid due to surface material change or tilt caused by measurement errors and other problems; It can accurately measure the thickness of multiple layers of transparent workpieces, and can also be used for 2D profile measurement and surface roughness measurement in the laboratory, to industrial online detection, automated control, etc.

As a national high-tech enterprise, Liyi aims to create high-specification spectral confocal displacement sensors and reduce the cost of popularization and promotion, bringing together optical, mechanical, software talents and partners in the field of spectral confocal work day and night, grinding a sword for several years, developing a commercial product series of precision spectral confocal displacement sensors with independent intellectual property rights, mastering the core technology. Break the blockade to make up for the gap, and on the basis of the original has been greatly improved and applied for a number of invention patents.