2022-07-04

Many display components in our life and work can often see that this is a thin glass sheet with a flat surface, and the thickness of the glass substrate in commercial use is 0.7mm and 0.5m, as well as ultra-thin glass for special fields, so the accuracy requirements are very high.

So how to measure the thickness of the glass substrate?

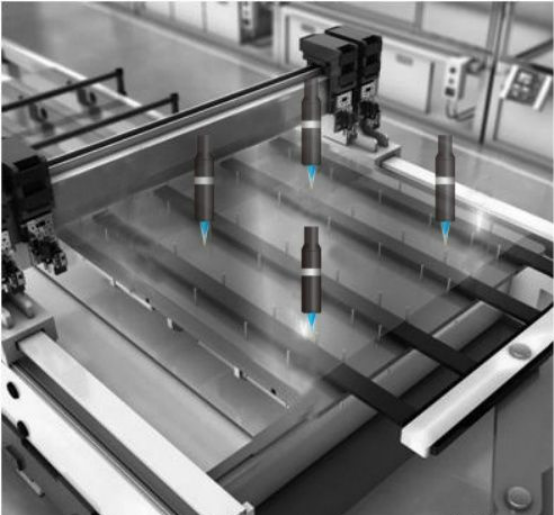

The traditional measurement contact measurement not only the accuracy can not be guaranteed, and it is easy to cause secondary damage to the glass surface, so what is the way? In 2014, Shenzhen Liyi Technology Co., Ltd. independently developed and processed non-contact measurement spectral confocal displacement sensor. The spectral confocal sensor has the characteristics of high precision, high stability, large Angle, high sampling frequency, etc., and has unique advantages for the thickness measurement of transparent or opaque mirror/semi-mirror reflective materials such as plastic film, glass, high-light metal, and multi-layer transparent materials.

The spectral confocal sensor can be measured with a single head thickness gauge or a double head according to different material measurement requirements. For transparent materials, single probe is used for measurement.

Because the thickness of the glass substrate is very thin, and the thickness size control is very strict, generally at a tolerance of 0.01mm, the main accurate measurement of glass thickness, warping and parallelism. The spectral confocal sensor of the vertical instrument is used to solve this problem and prevent secondary damage.