2022-07-02

On the high-precision production line, 3D visual inspection technology plays an important role in product identification, detection, size, etc., but it is very vague for those who do not know much about it. The following editor will introduce you to the role of 3D visual inspection in the workshop for everyone to understand.

First, image recognition applications:

Image recognition is the use of 3D machine vision to solve, analyze and understand the image to identify a variety of different ways of overall goals and objectives.

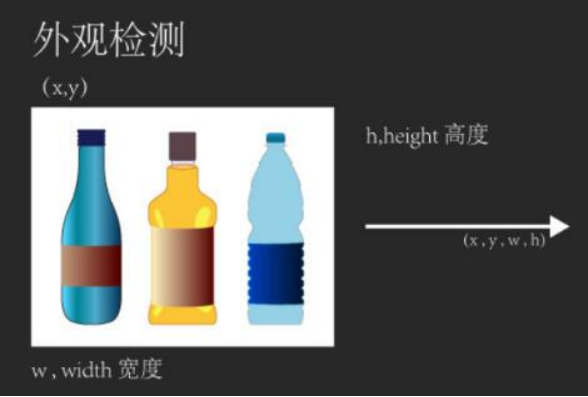

Second, image detection application:

Inspection is the most important application of machine vision industrial production, because manual inspection is not only low efficiency, long-term work even accuracy can not be guaranteed. Therefore, machine vision is also very common in the application of image detection, such as defect detection of glass bottles, bottle thickness detection and measurement.

Third, object accurate measurement application:

The biggest feature of machine vision industrial production applications is its non-contact measurement technology, which has the characteristics of high precision and high-speed operation, but it is non-touch without damage, and it removes the secondary damage safety hazards that are likely to be caused by precise touch measurement. Common precision measurement applications include transmission gears, connectors, automotive parts, IC component pins, twist drill bits, and roodin external thread inspection.

After listening to the introduction of Liyi Technology, I believe that everyone has a general understanding of "What are the applications of 3D visual inspection in the production of water", and more inquiries are welcome to pay attention to the company.