2022-06-07

With the development of science and technology, the demand for high-precision products is getting higher and higher, Liyi Technology is a professional production and development of laser displacement sensor, spectral confocal displacement sensor, white light interferometer, film thickness instrument company, and then Liyi Xiaobian will take you to understand laser displacement sensor.

What is a laser displacement sensor?

As the name suggests, laser displacement sensor is a sensor that uses laser technology to measure. It consists of a laser, a laser detector and a measurement circuit. It can accurately measure the position, displacement and other changes of the measured object without contact.

Can measure displacement, thickness, vibration, distance, diameter and other precise geometric measurements. The laser has the excellent characteristics of good straightness, and the same laser displacement sensor has higher accuracy than the ultrasonic sensor we know. However, the laser generation device is relatively complex and large, so the application range of the laser displacement sensor is demanding.

What are the specific applications of laser displacement sensors?

1, size determination: location identification of small parts; Monitoring whether there are parts on the conveyor belt; Detection of material overlap and overlay; Control of manipulator position (tool center position); Device condition detection; Detection of device position (through small holes); Liquid level monitoring; Measurement of thickness; Vibration analysis; Crash test measurement; Automobile related tests, etc.

2. Thickness measurement of metal sheet and sheet: Laser sensor measures the thickness of metal sheet (sheet). Thickness changes can be detected to help detect wrinkles, small holes or overlaps to avoid machine failure.

3, cylinder cylinder measurement, while measuring: Angle, length, inner and outer diameter eccentricity, cone, concentricity and surface profile.

4, length measurement: The measured component is placed on the conveyor belt in the specified position, the laser sensor detects the component and measures it at the same time with the triggered laser scanner, and finally the length of the component is obtained.

5, uniformity check: put several laser sensors in the tilt direction of the workpiece movement to be measured, directly through a sensor to output the measurement value, in addition, you can also use a software to calculate the measurement value, and read the result according to the signal or data.

Electronic component inspection: With two laser scanners, the component under test is placed between the two, and finally the data is read through the sensor to detect the accuracy and integrity of the component size.

7, filling level inspection on the production line: laser sensors are integrated into the production of filling products, and when the filling product passes through the sensor, it can detect whether it is filled. The sensor uses the laser beam to reflect the surface extension program to accurately identify whether the filling product is qualified and the amount of product.

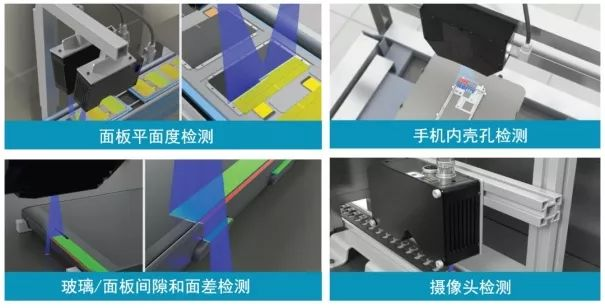

The above is all the content of "What are the applications of laser displacement sensors" introduced by Liyi Technology. Since its establishment in 2014, the products have accumulated rich experience in 3D glass measurement, LTCC thickness measurement, thread hole measurement, and glue thickness measurement. 3D glass measurement includes optical lens thickness, various transparent glass thickness, mobile phone glass thickness measurement, display thickness measurement, etc. LTCC thickness measurement includes crystal shape measurement, mobile phone metal step height measurement, silver paste thickness measurement and new energy battery electrode thickness measurement. Thread hole sounding refers to the depth measurement of the thread hole. Glue thickness measurement refers to transparent glue thickness and profile measurement and various precision measurement.