2022-05-19

Nowadays, smart phones play a very important role in our life, electronic products have very high precision surfaces, their appearance is generally made of very fine metal and glass synthesis. These materials, made of plastic, metal and glass, must fit together tightly and seamlessly.

As an advanced processing technology, color laser coaxial displacement meter plays an important role in the manufacturing process of mobile phone, and the application prospect of color laser coaxial displacement meter in the mobile phone industry is broad. The color laser coaxial displacement meter sensor ensures that all parts are aligned smoothly when assembled. These parts should not be touched during measurement.

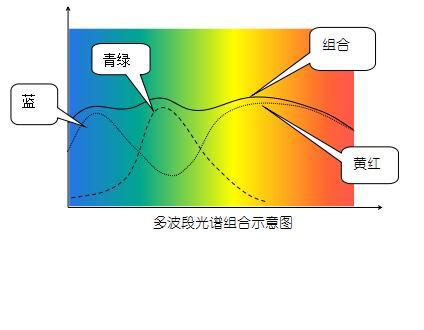

Color laser coaxial displacement meters are based on the principle of spectral confocal sensors, so white light is used, white light is synthetic light, and there is always light that can be reflected back. In addition, for curved surfaces, the Angle of reflection (45) of the light pen is increased, making it possible to measure the outline of the white transparent adhesive perfectly.

Color laser coaxial displacement meter chip processing: chip fitting, oled and led chips

The metal oled display covers can detect surface defects using ert line sensors. Color laser coaxial displacement meter sensors are also suitable for compact led chip packages with high luminosity miniaturization, such as led backlight and lcd screens. The cut profile or surface topography of these products can be measured. During product assembly, ert's color laser coaxial displacement meter sensors help detect whether the chip is installed in the correct position.

At present, a single led is no longer used, replaced by a highly integrated light-emitting diode chip. Non-contact color laser coaxial displacement meter sensors are often used when detecting optical chips, and they can easily measure the height of the led (in the z direction).