2022-05-19

White interferometer, spectral confocal displacement sensor, line laser displacement sensor, film thickness meter are all high-precision detection instruments, this vertical instrument technology small series will lead you to understand the principle of white interferometer and its application:

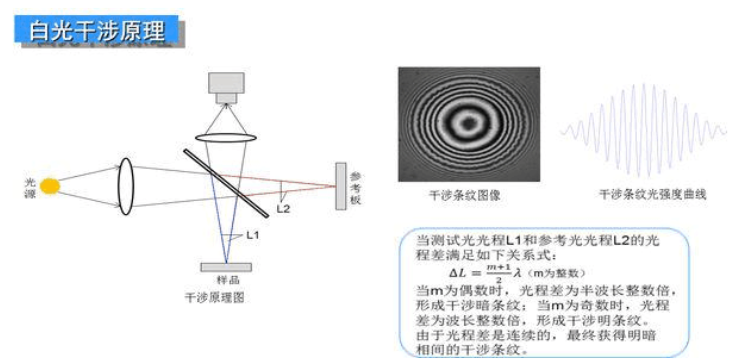

How it Works:

The light emitted by the light source is divided into two beams after the beam is expanded and collimated by the beam splitting prism. One beam is reflected back by the measured surface, and the other beam is reflected by the reference mirror. The two beams of reflected light eventually converge and interfere. The white light interferometer is an ultra-precision surface profile measuring instrument developed by using the principle of optical interference. The illumination beam is divided into two beams by the semi-reflective semi-permeable spectroscope and projected onto the sample surface and the reference mirror surface respectively. The two beams of light reflected from the two surfaces pass through the spectroscope again to synthesize a beam of light, and the imaging system forms two superimposed images on the sensitive surface of the CCD camera. Because the two beams of light interfere with each other, the interference fringes between light and dark are observed on the sensitive surface of the CCD camera. The brightness of the interference fringe depends on the difference of optical path between the two beams. The relative height of the measured sample can be determined according to the brightness of the white light interference fringe and the position of the interference fringe.

Applications:

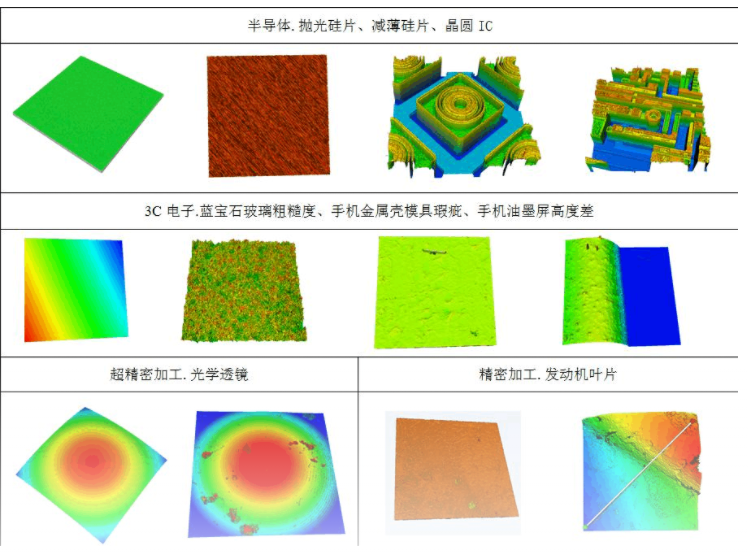

The white light interferometer is used to measure the three-dimensional micromorphology. White light interferometer can be widely used in semiconductor manufacturing and packaging process testing, 3C electronic glass screen and its precision accessories, optical processing, micro and nano materials and manufacturing, auto parts, MEMS devices and other ultra-precision processing industries and aerospace, national defense, military, scientific research institutes and other fields. It can measure all kinds of objects from super-smooth to rough, low reflectivity to high reflectivity surface, from nano to micron level workpiece roughness, flatness, micro geometric profile, curvature, etc., provide more than 300 kinds of 2D and 3D parameters according to ISOIASMEEUR/GBT four domestic and foreign standards as evaluation criteria.

Vertical Instrument Technology is a company specializing in the production of spectral confocal displacement sensors, white light interferometers, film thickness meters, line laser displacement sensors, since its establishment in 2014, has been focusing on high-precision measurement.