2022-05-11

Customer requirements and equipment: In the high-speed rotating machine, the bottle is moving to the scanning position, and the high-speed rotation cannot grasp the minimum value, resulting in poor repetition accuracy:

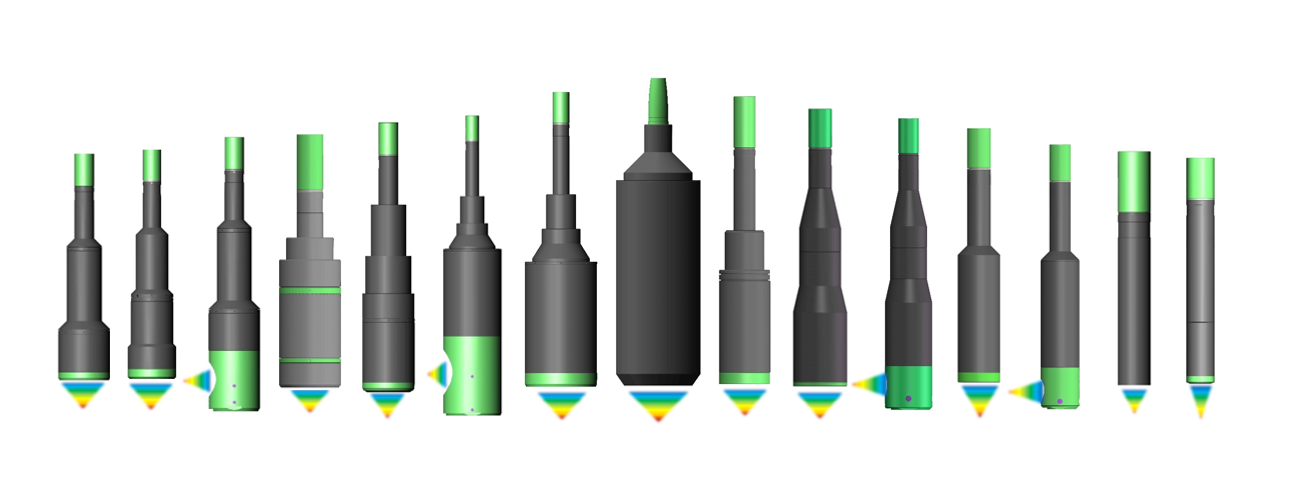

Measurement scheme: Using D35A18 unilateral thickness measurement and spectrometer spectral confocal controller, we adopt a trigger signal to collect multiple frames. When the beer bottle moves to the position, we give a signal to continuously collect multiple frames.

Then the other software takes 150-500 points data according to the rotation speed, to ensure that the number of points to finish the bottle for more than a week, and to take the lowest value.

Measurement scheme:

1. The actual problem is more complicated. There is a film gap in the bottle body, and the lowest value is generally at the film gap. Sometimes there is no complete wave peak at the film gap, and the signal is poor.

2. Because the site measurement environment is more complex, the bottle wall thickness is 0.5-5mm, so we need to do the incident Angle calibration.

3. After filtering is enabled, if the film gap appears at the edge of the taking point, serious data fluctuations will occur. In the process of abnormal data processing, since the algorithm is calculated according to the difference between two adjacent points, it also needs to be modified.

4. The customer requires the same measurement value under different machine speeds. After field testing, it is found that the rotation speed of the bottle is different under different machine speeds, so the scanning graphs under the same taking points are different, and the algorithm is calculated according to the point interval, which also produces the differences under different machine speeds.

We need to change the rotation after changing the machine speed so that the scan pattern is similar.

5.Transparent bottles and brown bottles can be measured stably, blue bottles light intensity is weak, can not be tested stably, is a problem in the industry.

6. The customer's requirement for repeatability is within 0.05mm, and the data stability requires a higher number of filtering times, so the truth value may be biased, and the customer can accept it.

Shenzhen Liyi Technology was founded in 2014, located in Longgang District, Shenzhen, is a precision optics private high-tech enterprise specializing in the production and sales of spectral confocal displacement sensors, laser displacement sensors, white light interferometers, film thickness meters and supporting solutions.