2022-04-26

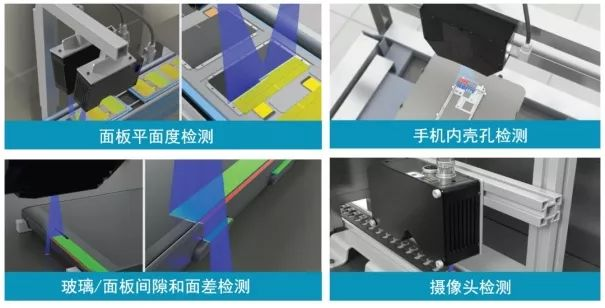

The development of science and technology, the rapid replacement of electronic products, directly requires the high requirements of detection accuracy and efficiency, for the current requirements, the technology team has been dedicated to research and testing and finally launched a high-precision 3D line laser displacement sensor, the front editor has introduced the product and its specifications, this editor will focus on the application field, We understand the line laser displacement sensor.

The 3D line laser sensor, combined with Metus software's sophisticated built-in point cloud algorithm, enables the detection of multiple types of electronic components with higher data point cloud density, higher repeatability, faster detection speed, and stronger processing power.

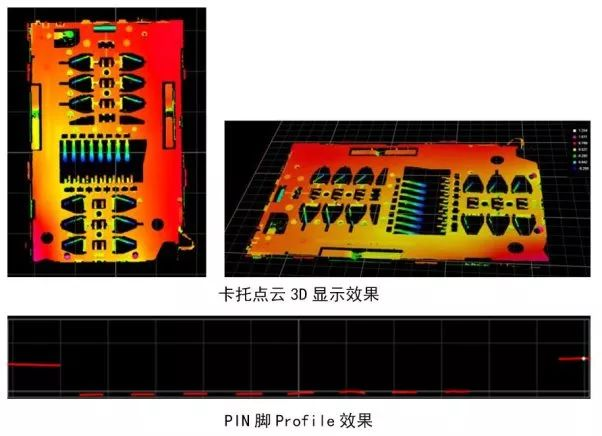

1 Smart phone SIM Card Detection Smart phone SIM card, is one of the hundreds of mobile phone parts. The height between the metal PIN on the card and the specified reference side must be checked. If the height between the PIN and the reference surface is too high, the SIM card chip cannot be contacted or the contact is unstable after the SIM card is inserted, and the mobile phone cannot detect the SIM card or cannot stably identify the SIM card. With the help of line laser detection can effectively eliminate this problem.

Line lasers are faster, have shorter exposure times, and scan point cloud data more completely, with finer detail and less noise. The use of line laser has improved the detection efficiency of production line by more than 50%, and the product yield has increased from the original 95% to more than 99.5%, which has brought considerable economic benefits and good reputation to customers.

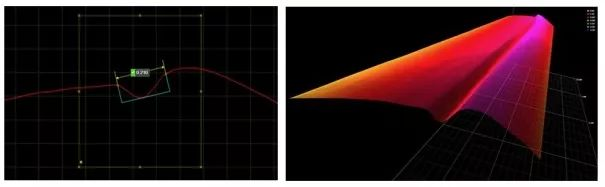

2 Online inspection of connector pins Connector pins are highly reflective tiny objects, to achieve the required accuracy to meet geometric tolerances, scanning and measurement become very difficult. In particular, there is often noise in the scanning data between pins. In addition, some pins require the sensor to have a large measurement range in order to accurately obtain the pin geometry.

Figure | 3D scanning of connector pins Benefit The line laser sensor generates a high density 3D scan data for each highly reflective pin, allowing users to obtain the highest resolution image, enabling the connector to be fully and clearly detected.

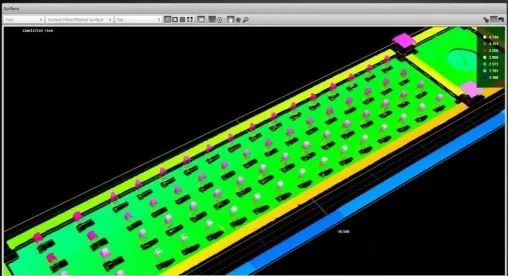

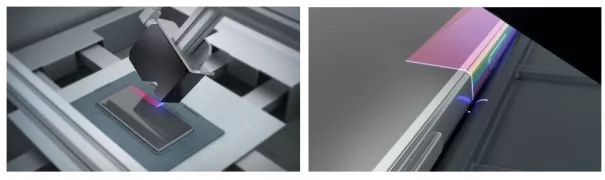

3 The quality control detection of scanning glass, bright metal and plastic of mirror and diffuse reflective materials such as glass is a big difficulty. Line laser sensors with optimized precision design and unique scanning capabilities provide superior 3D data for glass and other mirror scans and complete inspection at speeds up to 10 kHz (scanning, measurement and control in one, combined with Metus' rich measurement algorithms). In addition, using professional laser projection technology, the sensor ADAPTS to the detection of objects at different angles, and it also has excellent performance for a wider range of mirror materials and color scanning detection (such as anti-glare, coated/uncoated, low/high contrast, transparent and glossy materials).

The line laser sensor simultaneously scans the mirror and diffuse materials. The line laser sensor simultaneously scans the outer frame and the glass edge of the frame to generate high-resolution 3D scanning data. The Metus point cloud algorithm is used to detect gaps, surface and segment differences, flatness, etc. The scanned point cloud can also be exported to the 3D inspection software, which can achieve rapid analysis and measurement of components in the quality control process, and quickly and accurately complete the first part inspection.

Using the built-in algorithm tool to detect gap and surface aberrator technology line-driven sensing solution, the image and laser scanning are unified in the same equipment, the same program, and the same coordinate system to complete the product size detection, which meets the requirements of the coordinate system unification in the design of precision testing instruments, provides higher efficiency for the verification and detection link of consumer electronics lines, and meets the requirements of modern production lines.

Through the introduction of vertical technology, the corresponding line laser displacement sensor for those fields have a general understanding, Shenzhen vertical technology is a professional production and development of point-line spectral confocal displacement sensor, 3D line laser displacement sensor, spectrometer company, since its inception, products are professionally used in glass detection, chip detection, semiconductor detection, segment difference side thickness and other high-precision measurement.