2022-04-11

With the progress of science and technology, in the background of the strong development of industry 4.0, the previous 2D vision has been far from meeting the needs of the current industry, in the continuous exploration and progress, 3D vision inspection application, the following small series of Lihe technology to uncover the mystery of "3D vision line confocal sensor" for you:

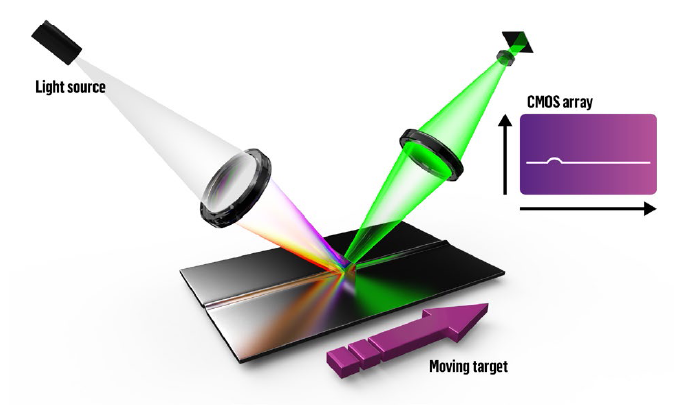

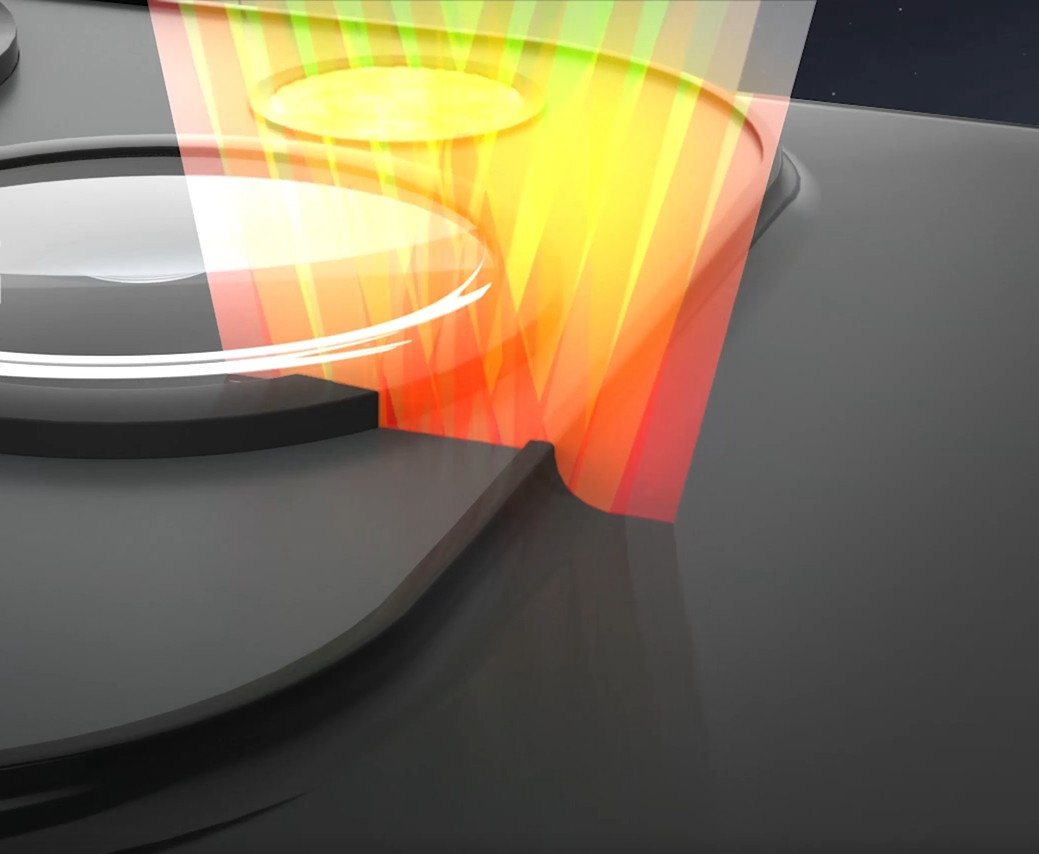

01 line confocal imaging principle:

3D line confocal technology is an optical detection method based on transverse color difference, which divides the white light emitted by the emitter in the sensor into a continuous wavelength spectrum. Each wavelength is focused on the surface under test at a certain distance from the sensor to form a vertical focal plane. This technique is suitable for coaxial design of single point and multi-point geometry and off-axis design of line geometry. So what are the advantages of 3D line confocal? First, the line confocal sensor can simultaneously generate 3D, 2D and tomography images with extremely large focusing depths. The sensor is suitable for measuring highly reflective, mirror, transparent, curved, tilted, high-contrast, flexible, brittle and porous materials, and can even measure the thickness of clear coatings and air gaps. It is widely used in the quality inspection of glass, polymer/plastic, metal, composite materials, ceramics, biological materials and other materials.

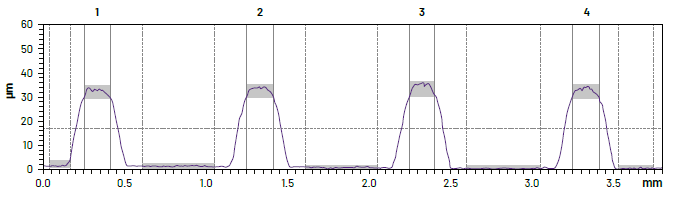

Mobile phone profile scanning:

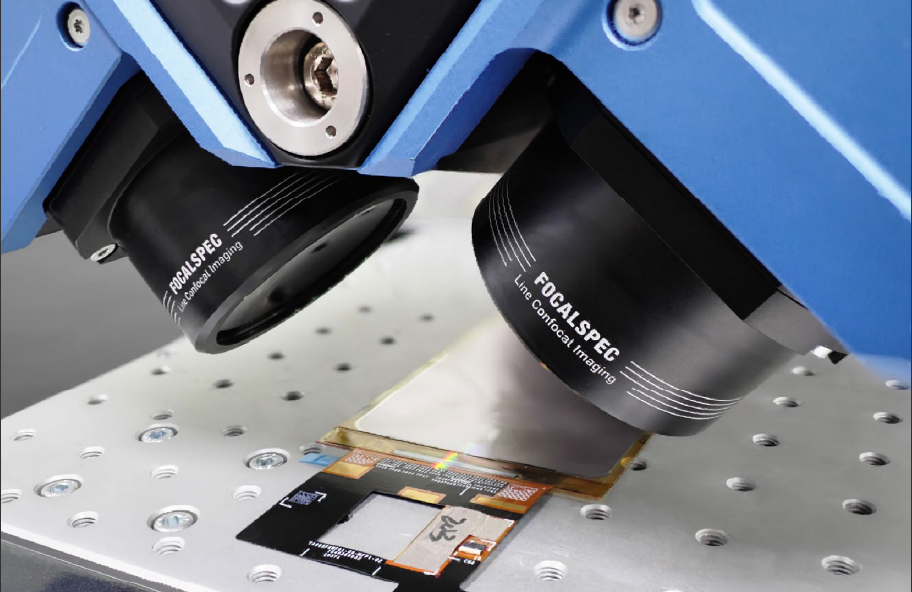

Line confocal sensors are ideal for measuring printed electronics, combining 3D topography, tomography, and 2D intensity imaging in a single sensor image. It is used for quality control of hybrid electronics and coated transparent bearer substrates to detect delamination, scratches, impurities, air gaps, bubble defects.

OLED display online detection:

The OLED display manufacturing process consists of a multi-step process, mainly including:

1. Cells end

2. Module end

Each step in these manufacturing processes relies on 100% in-line inspection using 3D machine vision technology, in addition to obtaining high-definition height data, surface defect detection and scanning transparent materials such as rubber paths and multiple layers of OLED displays.

The product combination of 3D smart sensors and 3D line confocal sensors provides fast, accurate and cost-effective 3D solutions for screen display applications. By networking multiple sensors, engineers are able to build in-line inspection systems for high-throughput assembly verification.

3D line confocal sensor is a product independently developed by Lihe Technology, using coaxial optical path design, can achieve fast 3D scanning, greatly improve the detection efficiency, and high accuracy, material and Angle adaptation. More inquiries, welcome to pay attention to Liyi.