2022-03-25

3D measurement technology based on line laser is a new non-contact measurement method in recent years. It can measure the surface topography of 3D objects with large area and high resolution by means of high-speed laser scanning. Because of its fast, non-contact and high precision, it is widely used in industrial on-line measurement field.

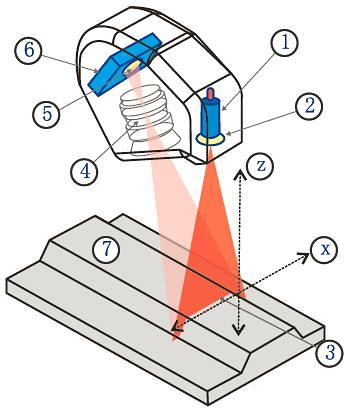

1. System composition

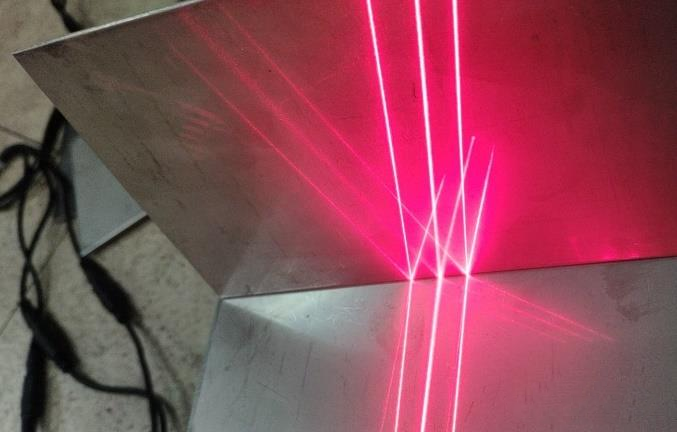

The laser measuring instrument adopts the principle of laser triangulation, using the transmitter to project the laser onto the surface of the object to be measured, and the complete contour measurement results can be obtained through the movement of the sensor/object to be measured.

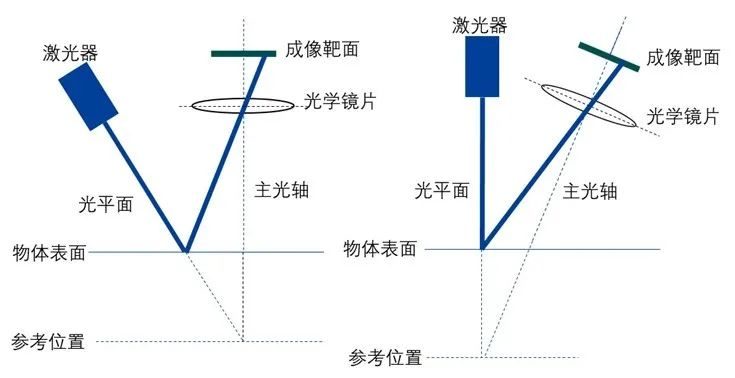

Line laser measuring instrument according to the different incidence mode can be divided into oblique and direct beam type two:

Ii. Relevant cases

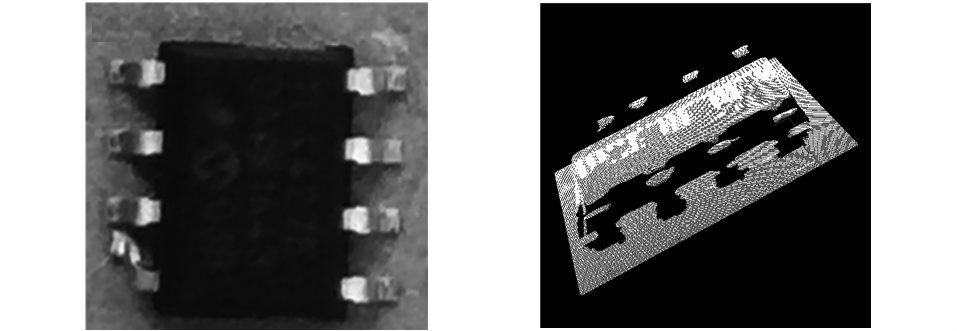

1, chip pin coplanarity chip pin coplanarity guide foot vertical height deviation, that is, the vertical deviation between the bottom of the low pin and the bottom of the high pin, generally shall not exceed the pin thickness. The lack of coplanarity will lead to the dislocation of the patch solder joint, the offset of the pin, and the scratching of the substrate when it is too large.

Chip physical image, three-dimensional point cloud image

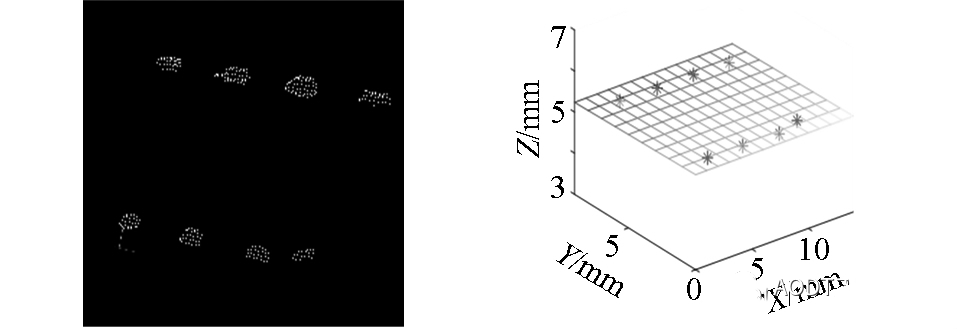

Chip pin segmentation diagram, fitting pin plan

3D scanning of the chip can be realized by using line laser measuring instrument and 2D motion platform. The maximum distance from each pin to the plane is calculated after pin segmentation and plane fitting. If it is less than the threshold, the coplanarity is qualified.

2, weld detection welding technology is widely used in petrochemical, automobile manufacturing and other industrial fields. The quality of the weld determines the overall quality of the device, so the detection of the residual height and width of the weld has been one of the key research objects in the industry.

The welding quality can be measured online by using a line laser measuring instrument combined with a six-axis welding robot. At the same time, automatic correction of the trajectory before welding or automatic polishing of the weld after welding can be realized.

3, car clearance surface difference Car clearance surface difference is one of the important factors to determine the appearance of the vehicle, but also directly affects the vehicle's water leakage performance and noise suppression performance; Therefore, the measurement of gap surface difference is also one of the important detection steps when the car leaves the factory.

Summary With the rapid development of vision-based measurement technology, line laser measuring instrument has been widely used in the field of industrial testing with the advantages of non-contact, high precision and fast speed, effectively ensuring the accuracy and timeliness of industrial online measurement.