2021-12-02

Today, in the face of the development status of domestic precision measurement, Shenzhen Liyi Technology Co., Ltd. carefully researched and developed to create a spectral confocal displacement sensor with high precision, high stability, high universality and other advantages, which added help to break the dilemma of China's manufacturing industry. Today, many people do not understand the spectral confocal sensor and ordinary laser displacement sensor, today by Shenzhen Liyi Technology Company to introduce the difference between spectral confocal sensor and ordinary laser displacement sensor:

Spectral confocal sensor is a non-contact displacement measurement system with accuracy up to the order of micro and nano, which can measure the displacement and thickness of diffuse/specular reflection and transparent multi-layer materials, and is also suitable for deep hole/blind hole workpieces.

Spectral confocal sensor Features:

1, non-contact optical confocal measurement technology, with ultra-high resolution and the same optical axis return signal will not be blocked characteristics.

2, optical fiber transmission color coding probe design, its structure is light and does not contain electronic parts and is not affected by environmental interference.

3, the use of white light (visible light) light source system, compared to laser light source safety protection requirements are low.

4, unique multi-layer material quality measurement algorithm, can measure the thickness or gap between transparent/translucent multi-layer materials.

Advantages:

1, stable measurement of all kinds of materials, such as metal/ceramic/mirror/glass.

2, suitable for all kinds of workpiece topography (including deep hole/slope/arc) feature size measurement, such as height/segment difference/thickness/flatness/profile, etc.

3, high temperature and high pressure and other harsh operating conditions can also adapt to normal use.

The difference between spectral confocal sensor and ordinary laser displacement sensor.

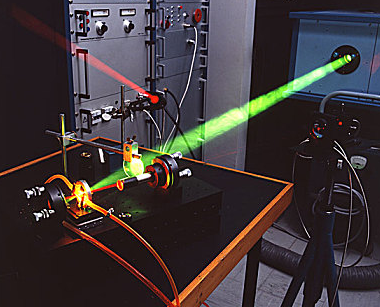

The spectral confocal displacement sensor uses white light as the measuring medium, while the laser displacement sensor uses laser. From a reasonable point of view, the spectral confocal displacement sensor can directly irradiate the measured object, because the white mixed light contains the spectrum of each color, and will produce a dispersion effect under the lens, the distance from the probe is different, the reflected light color will be different. The distal end is red, the proximal end is purple. By distinguishing the color of the reflected light, the sensor can know the distance between the object being measured and the probe.

There are several laser displacement sensors, including triangular reflection, pulse time difference, and phase difference. In general, the spectral confocal displacement sensor is more accurate, the spot is smaller, the measurement is more fine, but the price is more expensive and the adjustment has a certain technical content. Ordinary laser displacement sensors have been widely used.

Because the optical path of the spectral confocal sensor is very compact and concentrated, it is very suitable for measuring borehole structures. Using spectral confocal measurement technology, ultra-high resolution can be obtained. The nanoscale resolution results from the lengthened spectral range that has been specially treated above. Since the color of the focus is detected and the distance information is obtained, the spectral confocal sensor can adopt a very small measurement spot, which allows the measurement of a very small object under measurement. This also means that even a very slight scratch on the measured surface cannot escape the eye of the spectral confocal sensor.