2021-11-25

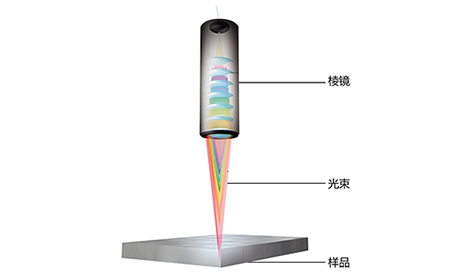

The spectral confocal displacement sensor emits a beam of high density and wide spectral light through the color laser light source. After passing the dispersion lens, the monochromatic light of different wavelengths in the range of travel, each wavelength corresponds to a distance value, and the measured light is reflected back to the surface of the object. Only the light that meets the confocal conditions can be sensed by the spectrometer through the small hole. By calculating the wavelength of the focal point of the sensed light, the obtained distance value is converted.

Glass substrate is a basic component of liquid crystal display device. This is a float method for producing thin glass sheets with extremely flat surfaces. The main thicknesses of glass substrates currently in commercial use are 0.7mm and 0.5mm, and thinner (e.g. 0.4mm) thicknesses are coming soon. Basically, a TFT-LCD panel needs to use two glass substrates, which are used as the bottom glass substrate and the bottom plate of the COLORFILTER.

Can provide large-size LCD screen glass substrate manufacturers only the United States Corning, Japan Asahi Glass four, of which the United States Corning accounted for 51% of the market, Japan Asahi glass accounted for 28% of the share, and can provide support for more than 5 generations of production lines are only these two, although the glass substrate only accounts for 6%-7% of the cost of TFT-LCD products, However, the technological oligopoly has made glass substrate products the dominant component of TFT-LCD upstream materials. The TFT-LCD glass projects undertaken by domestic Rainbow and Dongwook should receive special support and encouragement.

Because the thickness of the glass substrate is very thin, and the thickness size control is very strict, generally at a tolerance of 0.01mm, the main accurate measurement of glass thickness, warping and parallelism. ERT spectral confocal sensor is a good solution to this problem. Due to the confocal principle, the height value and thickness value can be collected in one measurement, and multiple sensors are used to measure at the same time, which not only improves the efficiency, but also avoids secondary damage caused by contact measurement.