2021-10-15

To improve the quality of Chinese manufacturing, it is necessary to improve the measurement accuracy, and the manufacturing of high-end equipment requires precision measuring instruments. However, the core technology of precision measuring instruments has been held in the hands of foreigners for a long time, and in the changing international situation, there is no doubt that China's manufacturing industry needs to master independent precision measuring instruments to break the dilemma of being "stuck" by foreign countries.

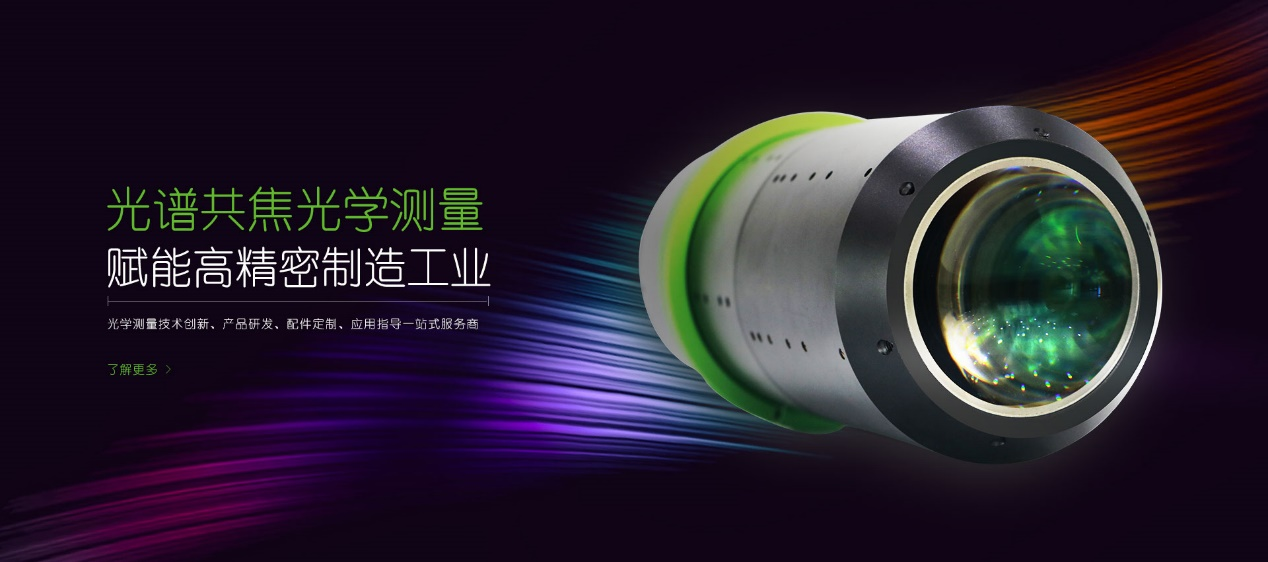

In the face of the development status of domestic precision measurement, Shenzhen Liyi Technology Co., Ltd. has carefully researched and developed to create spectral confocal displacement sensors with high precision, high stability, high universality and other advantages, adding help to break the dilemma of China's manufacturing industry.

Master the core principles and subvert the triangular laser ranging method

The spectral confocal principle adopted by the vertical instrument technology is expressed in popular words, that is, a beam of light is dispersed through a small hole through the lens to form a light band, and then the light band is illuminated to the surface of the object and the reflected light is collected, and the distance between the lens and the object can be obtained by calculating the wavelength and analyzing the reflected light. Different from the traditional triangular laser ranging method, it achieves the following breakthroughs:

1. The trigonometric method calculates the height distance according to the trigonometric function, and there are certain dead corners and blind areas, which is difficult to measure small pores; The spectral confocal ranging method adopts the coaxial measurement method of multi-irradiation, which can measure the traditional blind areas such as small holes and groove bottom.

2, triangulation method in the measurement of mirror, need to use a special instrument model or a specific Angle, and when the measurement surface tilt bending amplitude is large, it will produce no measurement light return, that is, can not be measured; When the spectral confocal ranging method measures the mirror, even if the bending and inclination amplitude is large, as long as a small part of the light is returned, the measurement can be completed without changing the model and Angle.

3, when the triangular method is used to measure translucent materials, it is easy to produce deviations, and the face of transparent materials is more "unable to start"; And the spectral confocal ranging method because the light around the translucent material light plate is blocked by the small hole can not return, so it does not affect the measurement, when measuring the transparent surface, not only can complete the measurement, and even can measure multiple layers.

4, triangulation measurement, because the laser focus is only thin, once it leaves the focus of the measurement area becomes larger, it will reduce the accuracy of the measurement; However, the effective wavelength of light measured in the range of the spectral confocal measurement method is always kept at the focus, and the resolution and accuracy are maintained in the full range.

Super stability, enabling precision measurement

The spectral confocal displacement sensor of Vertical instrument technology can easily deal with the measurement of metal, glass, mirror body, black rubber, ceramics and other materials, and the accuracy can be stably maintained within 1um, with high precision linear performance on various materials, relative to the traditional triangle laser displacement sensor, in the domestic precision measurement field achieved a new breakthrough. In practical applications, spectral confocal displacement sensors have also won high recognition by virtue of their distinct advantages such as high precision, high stability and high universality.

In addition, the spectral confocal displacement sensor can also be used in panel display, dispensing, measurement and other fields, such as smart device LCD panels, precision non-contact measurement, and panel electrode thickness measurement. In areas critical to people's livelihood such as transportation, new energy, and medical care, spectral confocal displacement sensors can also play an auxiliary role to help aircraft, high-speed rail, batteries, glass containers, and other manufacturing finer and better.

The superior performance of spectrometer confocal displacement sensor can play a full role in the semiconductor, chip and other components industry, and make great strides in "made in China" to "made in China" and strive to break through the predicament of foreign technology "jam neck" at present, which can add help to chip manufacturing. It is hoped that in the future, China's precision measurement can be further improved and make more contributions to the development of the overall manufacturing industry. I believe that in the near future, China's manufacturing industry will eventually master independent core technology, proudly standing in the world's strong forest.