2021-09-08

How does the spectral confocal sensor measure the glue height? At present, when the mobile phone center plate and screen module are fitted, it is necessary to point a circle of transparent UV glue on the center plate. This glue can only be measured perfectly using the spectral confocal sensor due to the white reflection. Due to the composite light characteristics of the spectral confocal sensor, the height and width of the glue can be measured perfectly at high speed.

In order to more visual experience, after the fringe screen, full screen, slide screen, double-sided screen, the hole screen also came. The hole hole is divided into two kinds of technology: through hole and blind hole. Through the hole is a hole in the screen, for the front camera imaging is more favorable, after all, less a layer of barrier, but the process is relatively more complex, the quality control requirements are more stringent, the yield is lower, there is a problem is that the aperture is larger, generally more than 6.5mm. The blind hole is to put the camera under the screen, the process is relatively more mature, the yield is high, the cost is low and the aperture is small, but because of the extra layer of liquid crystal, it is bound to affect the transmittance, and the image quality of the camera will also have a certain impact.

The "through hole" can effectively reduce the screen layer's blocking of the front camera, so that it has an advantage when taking photos to obtain light. Therefore, to solve the problem, you only need to consider the place where the screen is punched and the camera is well connected, this process has high requirements for the height of the dispensing, if the height of the glue is inconsistent, the imaging effect of the final screen has a gap and the connection is not natural. The use of spectral confocal sensor can be a good solution to this problem, not only can fully measure the height of the glue, but also can measure the width, high-speed sampling frequency, more suitable for automated equipment online.

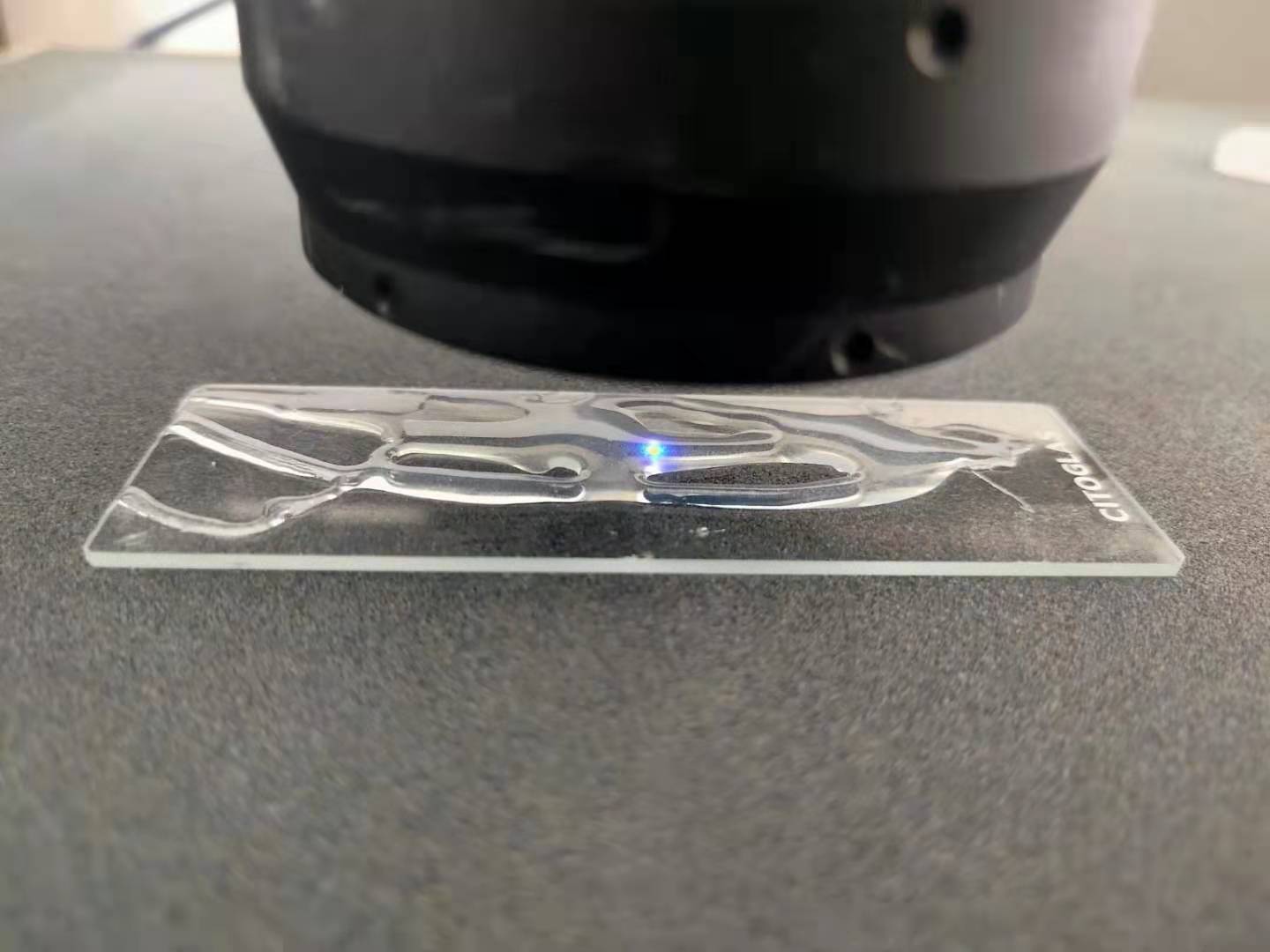

When the camera module is installed, because the glue dispensing is transparent glue, there are two difficulties in the detection of this glue, one is that after dispensing, the shape of the glue is curved, which is a very test of the mirror reflection Angle of the light pen, if the monochrome laser sensor detection, it will cause the light to penetrate, the laser directly penetrates the glue bottom, or the reflection Angle caused by the arc. Can't reflect light back.

Therefore, the current common practice in the industry is to use a large Angle spectral confocal sensor, because the spectral confocal sensor uses white light, white light is composite light, there will always be light can be reflected back, and for the arc, increase the reflection Angle of the light pen (45°), so as to perfectly measure the outline of the white transparent glue.