2021-08-27

With the development of confocal spectroscopy technology, we can see the measurement of almost all types of materials, flatness, camboid, height difference, grooves, etc., applied to 2.5D/3D curved glass and other mobile phone 3C industry.

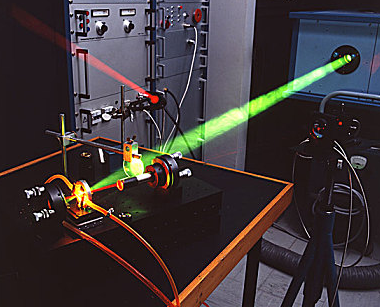

The spectral confocal measurement method takes advantage of this physical phenomenon. Spectral confocal measurement technology analyzes the focusing position of different wavelengths of light on a specific surface to carry out high-precision dimensional measurement and micro-morphology analysis. According to this measurement principle, a specific wavelength of light may be focused on the front of the sample, while for a transparent sample, two different wavelengths of light are focused on the front and back of the sample. These are the two measurement modes provided by spectral confocal, the former is the displacement measurement mode and the latter is the thickness measurement mode. Today we take a look at the method of spectral confocal measurement with Lithometer Technology:

1. Displacement measurement mode

The displacement measurement mode outputs the height value in the Z direction, and the point cloud coordinates can be directly output after importing the displacement value of XY. This model is consistent with measurement methods such as three coordinates, structured light and laser triangulation, but the difference is that spectral confocal supports the measurement of reflective surfaces and has sub-micron measurement accuracy.

The displacement measurement mode is suitable for most precision dimensional measurement scenarios, providing a variety of measurement sampling options such as point, line and surface. Point measurement is suitable for measuring object vibration and liquid height, and output Z-direction values of different time series to assist analysis. Line measurement can continuously record the Z-direction value of the moving sample surface for break difference detection and 2D dimensional analysis. Surface measurement provides complete 3D topography data of the sample surface for comprehensive analysis including roughness and other items.

2. Thickness measurement mode

When measuring transparent samples such as glass and lens, two beams of light of different wavelengths are focused on the positive and negative surfaces of the sample, and the thickness of the sample can be calculated after introducing the parameter of the refraction coefficient of the sample. Compared to traditional contact measurement tools such as vernier calipers, spectral confocal measurement has all the advantages of non-contact optical measurement, but also has the characteristic of obtaining the sample thickness value by measuring in one side.

The refraction coefficient directly affects the data accuracy of thickness measurement, so the refractive index of the sample should be confirmed at the beginning of measurement. The refractive index can refer to the value of similar materials, but for more accurate thickness measurements, the refractive index of the sample needs to be measured with an refractometer.

Mode switching

The two measurement modes of spectral confocal can be switched freely in the software interface without restarting the device or system. Therefore, whether it is to measure the surface size of the sample, or the thickness of the transparent material, or to obtain the appearance size and thickness information of the transparent sample at the same time, the spectral confocal measurement technology can be easily handled.