2023-02-11

In the new era, 3C electronic products such as mobile phones have become an indispensable part of people's lives, based on the public's high pursuit of product performance and quality, the application of 3C electronic manufacturing industry to machine vision detection has gradually increased. The following Liyi technology Xiaobian with an article to let you have a simple understanding:

1. Card slot detection scan

The internal structure of the workpiece is more complex, and some narrow slots need to be measured for their thickness, or width, etc. Our line laser can accurately scan its appearance through the way of the line.

Second, parts testing

As we all know in the 3C industry, all the parts are precise, and the traditional manual detection is not only time-consuming and labor-intensive, but also unsatisfactory. The 3D industrial vision sensor line laser perfectly solves this problem, not only does not damage the product, the effect is also very fast.

Third, mobile phone frame detection

The middle frame of the mobile phone is an important part of the mobile phone, which is used to support and carry various internal core components, so it has high requirements for its quality and needs to do a strict quality control. Using the line laser sensor combination can directly complete the mobile phone frame data scanning, automatically generate point cloud data, through the comparison of standard files, quickly determine whether the depth of the line area meets the requirements.

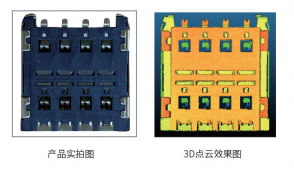

Fourth, keyboard height flatness detection

In the process of production, it is easy to have a large number of returns and exchanges because of the uneven height of the product, and the traditional detection time cost is high, and the quality of the product cannot be guaranteed. The emergence of 3D industrial vision sensors has solved this problem perfectly.

The 3D industrial vision sensor uses the laser triangle reflection principle and is suitable for a variety of industrial applications. Based on the self-developed CMOS imaging chip, the scanning speed is fast, the ultra-precision detection, the lateral contour data is up to 3840 points, and the shape of the measured object can be presented ultra-fine, to achieve ultra-precision measurement.