2020-11-24

Questions about laser displacement sensors

A laser displacement sensor has many units and details, for example, it can be divided into an internal processing unit, a transmitting and returning unit, a receiving unit of the laser receiver and an analysis unit. Because it can send out a large number of laser pulses per unit of time, it needs to receive the pulses back to the receiver as soon as possible. In recent years, in order to greatly reduce the processing time of laser displacement sensors, the sensor receiver has been optimized several times, so that it can be completed in a short time during long distance detection.

1, Why use laser displacement sensor

The development trend of laser displacement sensors is extremely fast, and in order to maintain the flatness of the glass, it is necessary to accurately control the temperature over a wider range. This is because if there is a temperature difference in the glass substrate, residual stress will be generated, resulting in bending and other glass deformation, or the glass deformation during the cutting process, thus affecting the stability of the glass substrate. And due to residual stress, after the polarizer is attached in the manufacturing process, the light phase difference will be generated, resulting in light leakage of the LCD module. Domestic laser displacement sensor manufacturers claim that stress can cause scars on the glass surface and damage the substrate.

2, the use of laser displacement sensor technical advantages

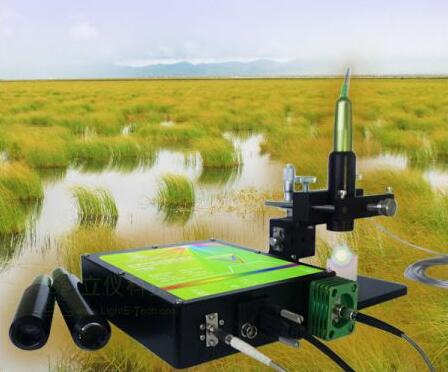

Laser displacement sensor can be used to measure the flatness of transparent materials successfully, which makes up for the shortage of traditional laser displacement sensor to measure transparent materials or mirror reflection, and expands the new application field of laser displacement sensor. The holographic sensor is based on a unique patented cone-light holography technology that outperforms existing standard ranging methods in a variety of industrial applications. The sensor is reliable, accurate and contains no moving parts. Compared with standard trigonometry, it has two advantages: collinearity and low electronic noise dependence. Non-contact distance sensors are used for automatic focusing of laser marking, welding, drilling and cutting systems.

In addition, the physical and chemical applications of laser displacement sensors can be analyzed from the perspective of measuring distance and speed. In addition to the above two conventional measurements, more important is the measurement of vibration. This microscopic measurement is commonly used in various high-tech industries, and physical quantities such as azimuth are often required to be measured when measuring vibration. For example, in the inspection of various physical pipelines, or in the process of air pollution and prevention, laser displacement sensors need to be used.