2021-11-26

Liyi Technology is a private high-tech enterprise with precision optical inspection as its main business, and spectral confocal displacement sensor and its application supporting products as its main products. The key research and development personnel of Vertical Technology have more than ten years of experience in the field of laser displacement measurement and 3D scanning, and found that spectral confocal is more accurate and adaptable than laser triangulation. The sensor is a product that some countries have imposed precision restrictions on exports to China.

We also provide local technical support, product selection, application consulting, test sample verification, supporting components, development assistance, non-standard customization, calibration and maintenance, so that customers can use comfortable, with rest assured.

The spectral confocal displacement sensor has been researched by a senior supervisor of ChongqingUniversity, ChongqingUniversity (CQU), referred to as ChongqingUniversity, located in Chongqing, as of March 2021, the school has 4 campuses, covering an area of more than 5200 mu, and the construction area of the school is nearly 1.7 million square meters; There are 36 second-level colleges and 99 undergraduate majors. There are 35 doctoral degree programs in first-level disciplines, 1 doctoral degree program in second-level disciplines, 53 master degree programs in first-level disciplines, and 25 professional degree authorization categories. There are more than 47,000 students in the school, including more than 20,000 postgraduates, 26,000 undergraduates and 1,700 international students in China. There are more than 5,300 faculty members, including more than 2,900 full-time teachers; The library has a total collection of 4,952,600 volumes.

Fortunately, the senior tutor of Chongqing University mainly studies the thermal stress of power semiconductors, thermal stress will produce deformation, and the spectral confocal measurement of vertical instrument technology can establish the deformation model.

I. Principle of spectral confocal:

1, online non-invasive, in situ characterization method

2. Optical chromatic aberration

2, the precise wavelength of light is focused on the object to be measured

4, by measuring the wavelength of the reflected light to determine the distance

5, Measuring range 0~150μm, accuracy 0.1nm

Two, deformation: spectral confocal method

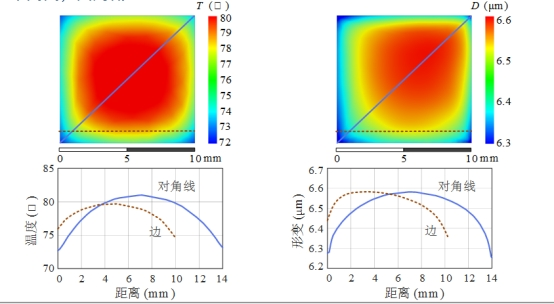

1. Thermodynamic coupling multi-physical field simulation

2. COMSOL multi-physical field simulation software

3, temperature distribution: high in the middle, low around

4, deformation distribution: high in the middle, low around

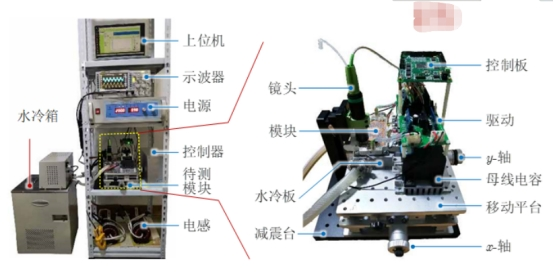

Deformation: test platform, thermal stress characterization platform of SiC power module

1. Power towing circuit topology

2, spectral confocal instrument (10nm resolution)

3, constant temperature water cooler (65℃)

4. Deformation: Experimental results

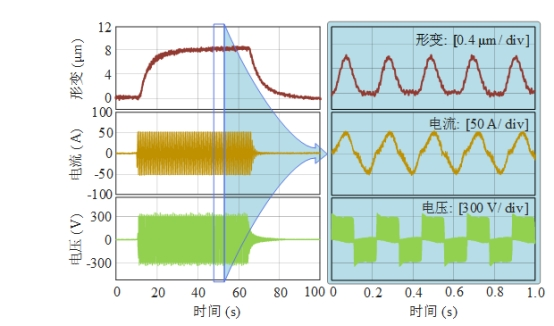

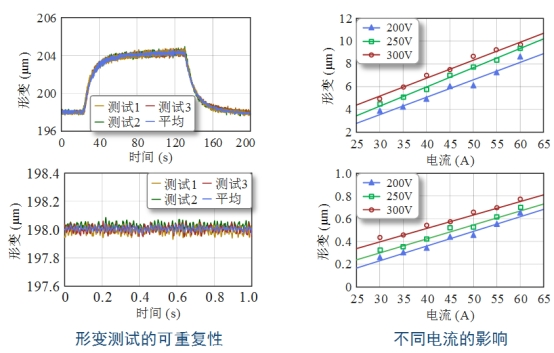

1. Constant power loading experiment

Voltage, current and deformation waveform

Deformation varies with the current

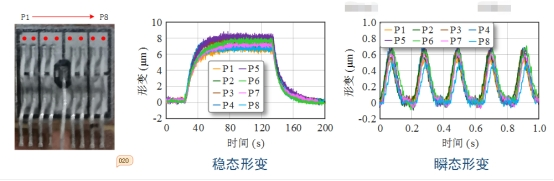

Deformation distribution of chip position

The transient deformation is 10% of the steady deformation

High in the middle, low around the sides

2, deformation is an inherent attribute of the power module

The steady state deformation is about 1μm/A, and the transient deformation is about 0.1μm/A

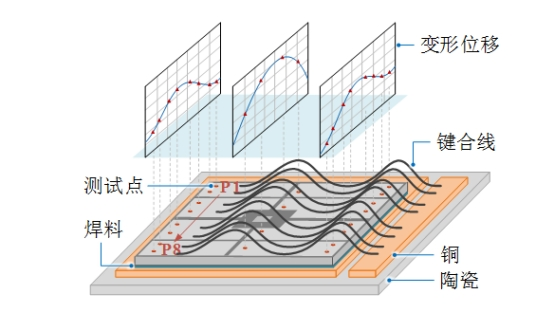

5, deformation: chip strain reconstruction, to point with surface, to reproduce the micro-deformation of the chip

1, chip deformation determines the failure of the solder layer

2, the chip center deformation is large

3, the chip edge deformation is small

4. The trend of steady-state deformation is consistent with that of transient deformation

5. Provide reference for chip and package design

The products have spectral confocal displacement sensors widely used in panel display/dispensing/measurement, 3C/ mobile phone/communication, aircraft, high-speed rail, automotive glass, car lights, rocket parts, part size measurement. Laser processing guide. In areas critical to people's livelihood such as transportation, new energy, and medical care, spectral confocal displacement sensors can also play an auxiliary role to help aircraft, high-speed rail, batteries, glass containers, and other manufacturing finer and better. In practical applications, spectral confocal displacement sensors have also won high recognition by virtue of their distinct advantages such as high precision, high stability and high universality.

This time, I would like to thank the tutor of Chongqing University for conducting a comprehensive experiment on the spectral confocal sensor and giving satisfactory experimental results. In the future, Shenzhen Liyi Technology Company aims to create high-specification spectral confocal displacement sensors and reduce the cost of popularization and promotion, bringing together optical, mechanical, software talents and partners in the field of spectral confocal work day and night, grinding a sword for several years, developing a commercial product series of precision spectral confocal displacement sensors with independent intellectual property rights, and mastering the core technology. Break the blockade to make up for the gap, and on the basis of the original has been greatly improved and applied for a number of invention patents.