2021-11-17

The VisionCon2021 VisionSystem Design conference, co-sponsored by ACTInternational and VisionSystemsDesignChina, will be held in Shanghai on November 19. The device manufacturers, system integrators, enterprise users and scientific research institutions in the machine vision industry chain will be invited to gather together to discuss the development opportunities of the latest machine vision technology in the manufacturing industry!

This meeting, Shenzhen Liyi Technology Co., Ltd. also accepted the invitation, and brought spectral co-alternating displacement sensor, color laser displacement meter, fiber coaxial displacement sensor and other products will be everyone's attention. Liyi Technology is a private high-tech enterprise with precision optical inspection as its main business, and spectral confocal displacement sensor and its application supporting products as its main products.

The key research and development personnel of Vertical Technology have more than ten years of experience in the field of laser displacement measurement and 3D scanning, and found that spectral confocal is more accurate and adaptable than laser triangulation. The sensor is a product that some countries have imposed precision restrictions on exports to China. Aiming at creating high-specification spectral confocal displacement sensors and reducing the cost of popularization and promotion, Lihe brings together optical, mechanical, software talents and partners in the field of spectral confocal work day and night, grinding a sword for several years, developing a commercial product series of precision spectral confocal displacement sensors with independent intellectual property rights, mastering the core technology, breaking the block to make up for the blank. And on the basis of the original has greatly improved and applied for a number of invention patents.

We also provide local technical support, product selection, application solution consultation, sample verification, supporting components, development assistance, non-standard customization, calibration and maintenance, so that customers can use comfort and rest assured. In line with the purpose of creating more value for customers, employees, investors and society, Liyi research and development is efficient, independent innovation, and provides excellent products and services for customers. Let science and technology benefit all sentient beings, looking forward to working with companies and people from all walks of life to work together to create brilliant!

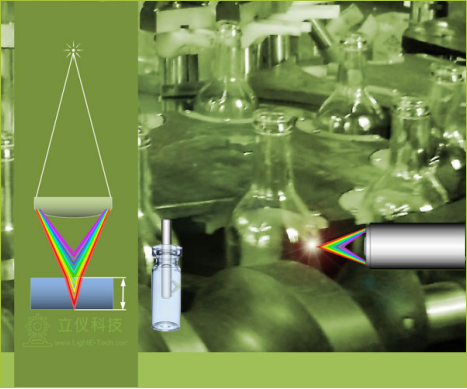

This product has a spectral confocal displacement sensor, which takes the principle of spectral confocal as the core principle, the principle of spectral confocal displacement sensor: A beam of white light (or multi-wavelength mixed light) passes through a small hole, through the lens to focus different wavelengths on the optical axis, dispersing to form a rainbow distribution band, only the light shining on the intersection of the optical axis and the surface of the object passes through the spectral component, irradiates through the small hole to the spectral analyzer, decoding the wavelength can obtain the distance between the lens and the measured object.

1. Advantages of spectral confocal principle

1, super stable measurement of any material

The spectral confocal displacement sensor can be stably measured within 1um accuracy on any surface, while the traditional triangular laser displacement sensor has poor measurement accuracy for mirror glass and other materials.

2, subvert triangular laser ranging method

The height distance is calculated according to the trigonometric function, and the shadow part in the figure is the blind area that cannot be measured. The triangulation method requires a special model or a specific Angle to measure the mirror, and the measurement position will change with the height. When the surface tilts and bends large, no measured light returns. The transmission of translucent materials has been proven to be biased, and transparent and mirror materials are difficult to measure. The laser is thin only at the focus, the spot becomes larger after leaving the focus, the measurement area becomes larger, the sampling area is uncertain, and the accuracy becomes worse.

3, modular miniaturization

4, FM anti-interference

The wavelength is an FM signal and is not sensitive to AM interference such as changes in light intensity. Optical fiber is not sensitive to electromagnetic interference and lightning surge.

2. Application field

1, panel display/dispensing/measurement

LCD panel, OLED, MiniLED equipment, multi-layer glass thickness, gap, panel electrode thickness measurement, etc.

Dispensing guide, glue height measurement, droplet, liquid level, transparent coating thickness measurement.

Precision non-contact measurement, instead of contact profile measurement, roughness measurement.

2. 3C/ Mobile phone/communication

Mobile phone camera frame, middle frame, card, segment difference, step, knife grain, assembly positioning, meat thickness, roughness, flatness, profile, hardware and plastic parts.

3D glass inspection, ceramic back cover, graphite mold, 5G ceramic component measurement.

Precision spherical, aspherical lens thickness, mobile phone/security camera, optical parts inspection, assembly positioning

3, aircraft, high-speed rail, automobile glass, car lights, rocket parts, parts size measurement. Laser processing guide.

Battery electrode, diaphragm, film, foil, glass, graphene, metal thickness (beam measurement), soft pack battery, blade battery size measurement.

Glass thickness measurement, glass bottle wall thickness, glass/ceramic container, screw nut inner groove, thread inner wall, engine cylinder, mirror plating parts measurement.

The conference will bring together important manufacturers from all aspects of the machine vision industry chain to discuss practical machine vision technologies, products and application solutions with enterprises and users. We look forward to in-depth exchanges with many outstanding enterprises in the industry, and jointly explore new ideas for the transformation and upgrading of China's manufacturing industry!