2021-08-16

In the spectral confocal displacement sensor system, the measuring range of the system is affected by four factors: 1) the spectral distribution range of the light source; 2) The axial color difference of the dispersion lens in the working band range; 3) The working band of the spectrometer; 4) The working band of the optical fiber coupler. The spectral distribution of the selected white LED light source is shown in the figure below, the band is 400 ~ 800 nm, so in the design process, the working band of the dispersive lens, the spectrometer and the fiber coupler should be as consistent as possible with the band of the light source, and the measurement range of the final system is the axial color difference of the dispersive objective in its common working band.

In the design of dispersive lens, in addition to its axial color difference, the following factors should be considered: 1) increasing the numerical aperture of object can improve the resolution; 2) Increasing the numerical hole of the image square can improve the utilization rate of the light source; 3) Reducing the spherical error of the system can improve the accuracy; 4) The system structure should be easy to assemble and adjust.

The above factors are mutually restricted, increasing the numerical aperture at the same time the system spherical error will also become larger, if you want to correct the spherical error system, the structure will become complicated, so the purpose of dispersive lens design is to use the least lens to achieve the best effect. The optical system of the spectral confocal displacement sensor can be seen as two parts, one part is the achromatic field mirror, its focus at the light source, the point light source collimation into parallel light, the other part is the dispersion objective, its role is to focus parallel light of different wavelengths at different positions on the axis, forming spectral dispersion, and achromatic lens and aspherical lens can play such a role.

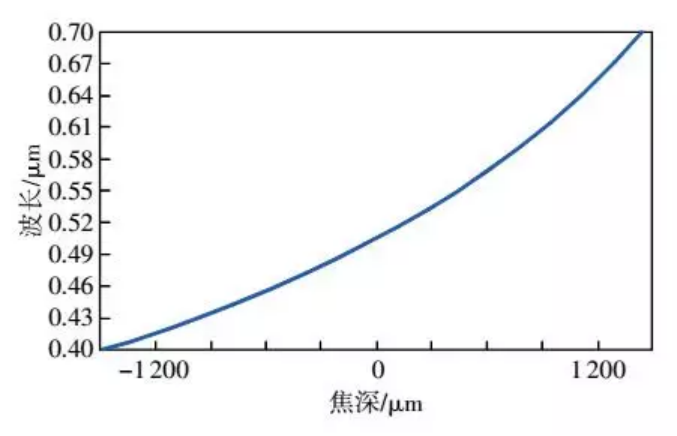

Through the simulation analysis of ZEMAX software, the dispersion range of the dispersing lens in the band of 400 ~ 700 nm is 2.3 mm, and the corresponding relationship between the specific wavelength and the focusing position is shown.

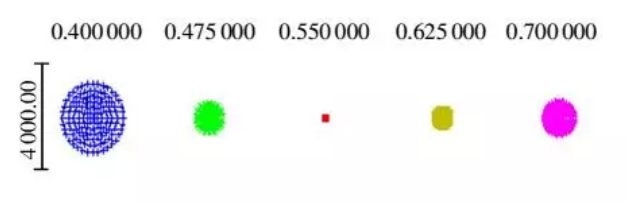

Because the system needs to analyze the spectral intensity distribution reflected back to the fiber, the confocal process is simulated. In the simulation process, the plane mirror is placed at the focal plane, so that the light passing through the optical system is reflected by the plane mirror and then returned to the optical system, and the image is formed at the position of the light source. By observing the point diagram at the image plane, it is found that when the plane mirror is set at the focal plane of different wavelengths, the dispersion spot at the image plane of focusing wavelength is smaller, while the dispersion spot at other wavelengths is larger.

Is the point diagram of the image surface when the plane mirror is set at the 550 nm wavelength telephoto plane. The diameter of the dispersion spot at 550 nm wavelength is 41.4 μm, which is smaller than the optical fiber core diameter, while the diameter of the dispersion spot at 400 nm wavelength is 2 311.46 μm, which is much larger than the optical fiber core diameter. In order to more accurately analyze the optical filter of the optical fiber core diameter to the confocal system, the optical fiber end face is discretized as a uniform point source with a spacing of 1 nm, and it is assumed that the overlap between the dispersion spot and the optical fiber core is the light that can enter the optical fiber.

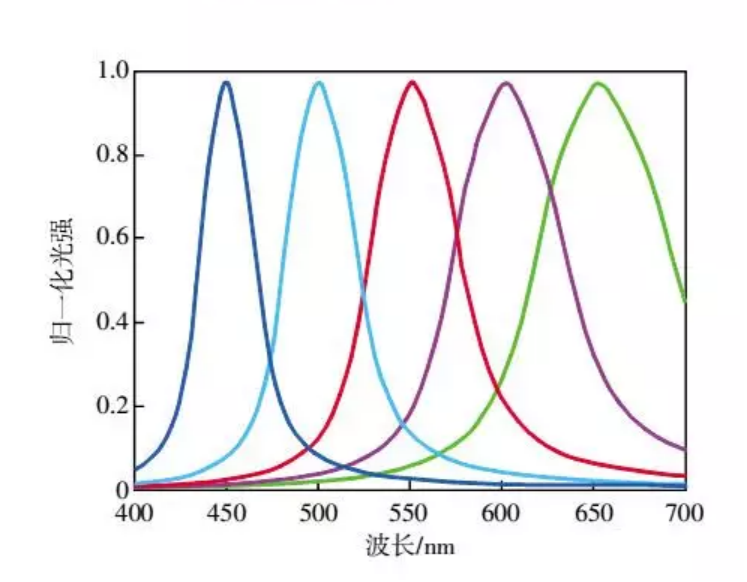

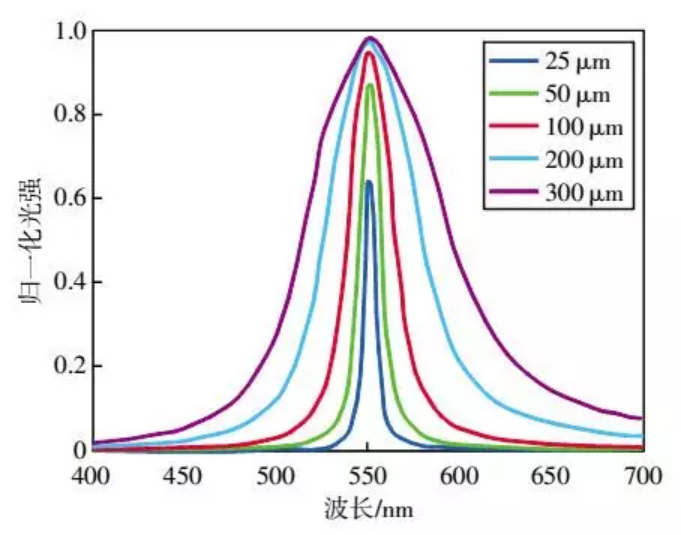

The spectral intensity distribution reflected back to the fiber when the plane mirrors calculated for this condition are set at the focal plane of 450,500,550,600,650 nm. It can be seen from the figure that the diameter of the optical fiber core plays a good role in light filtering, and the height and width of most of the fiber increase with the change of wavelength. The distribution of spectral light intensity reflected back to the fiber under different optical fiber core diameters is analyzed. In order to analyze the results when the reflector is set at the focal plane of 550 nm, it can be seen that when the optical fiber core diameter is small, the spectral signal energy is weak. With the increase of the optical fiber core diameter, the spectral signal energy becomes stronger but the half-height width also increases, and the resolution decreases. In the design, the appropriate optical fiber must be selected to meet the requirements of system resolution and signal-to-noise ratio.

After listening to the introduction of Liyi Technology I believe that everyone has a general understanding of "how to design the structure of spectral confocal displacement sensor". Liyi Technology, a private high-tech enterprise with precision optical detection as its main business, was founded in 2014, and independently developed a commercial product series of precision spectral confocal displacement sensor in nearly 10 years, more content, Welcome to Liyi Technology.